Italy's Marble Mountains: Where Michelangelo's Masterpieces Began

Deep in the Apuan Alps of Italy, at an altitude of about 1,000 meters, lies a treasure trove of the world's most sought-after marble. This isn't just any stone; it's the very same statuario marble that Renaissance master Michelangelo used for his iconic sculptures. Imagine, a single block can fetch over €1,000, and transforming it into fine slabs is a process that takes days. For over 2,000 years, the Carrara region has been a source of this magnificent material, but it's in the Apuan Alps where the truly exceptional is extracted.

Key Takeaways

- Ancient Roots, Modern Extraction: Italian marble has been quarried for millennia, with the Apuan Alps being a prime location for high-quality statuario marble.

- Michelangelo's Choice: The "statuario" marble, known for its unique white veining and light-passing qualities, was favored by Michelangelo.

- Intensive Mining Process: Extracting marble involves massive saws, careful block cutting, and a complex process to transport massive 120-ton blocks down the mountain.

- Precision and Craftsmanship: Geologists map marble veins precisely, and sawmills meticulously cut and polish slabs, a process that can take 20 hours per slab.

- Advanced Finishing: Slabs are treated with resin to fill hairline cracks, then sanded and polished using industrial diamonds, with costs reaching up to €300 per square meter.

- Global Reach: This Italian marble adorns projects worldwide, from mosques in Abu Dhabi to corporate headquarters in the US.

- Sustainable Future: The company emphasizes that their quarrying is sustainable, with vast reserves ensuring marble availability for thousands of years.

- Innovation in Art: The company uses 3D technology and collaborates with artists to create sculptures, blending manual skills with robotics.

The Majesty of Staturario Marble

Geologist Daniel Manani and his team are responsible for extracting thousands of tons of this precious material annually. What makes "statuario" marble so special? It's not just the pure white color; it's how light passes through it, revealing a subtle, intricate grain. This unique characteristic made it the preferred choice for artists like Michelangelo.

From Mountain to Masterpiece: The Extraction Process

The mining rights in this region belong to the company ENRO. Here, the process is a feat of engineering and sheer hard work. It can take workers up to 20 hours to cut a single piece from the rock face using enormous band saws and chainsaws for horizontal cuts. Once a block is freed, it weighs a staggering 120 tons. To move these giants, a cushion is inserted into the cut, inflated to create a gap, and wedges are used to carefully tip the block over. Even with all this care, blocks can sometimes crack along the veins, but even the broken pieces can often be repurposed.

Precision in Every Cut

Geologists play a vital role, meticulously mapping the different marble types found on the mountain. This is crucial because customers often order marble based on specific patterns for their projects. The goal is to cut blocks that are as suitable as possible for these unique commissions. This detailed mapping and planning happen multiple times a day, overseeing the entire production process.

The Art of Marble Slab Production

Once extracted, the massive blocks, some weighing up to 60 tons, are transported down the valley by truck. At the ENRO production facility, the real transformation begins. In the sawmill, these blocks are cut into fine slabs. This cutting process alone can take a full 20 hours, from one morning to the next. Gino Chenini, head of the sawmill, explains that this requires immense patience and a significant amount of water – about 1,000 liters per minute per machine. However, this water is part of a closed-loop system, meticulously cleaned and reused, minimizing waste.

Most stone saws are equipped with industrial diamonds, making them hard enough to cut through the marble. The next day, the cut slabs undergo further refinement. They receive a layer of resin, which is later sanded off. This resin treatment fills any hairline cracks in the marble, resulting in a perfectly smooth surface. These exquisite slabs can cost up to €300 per square meter and can be produced in various thicknesses, from several centimeters down to a mere 5 mm.

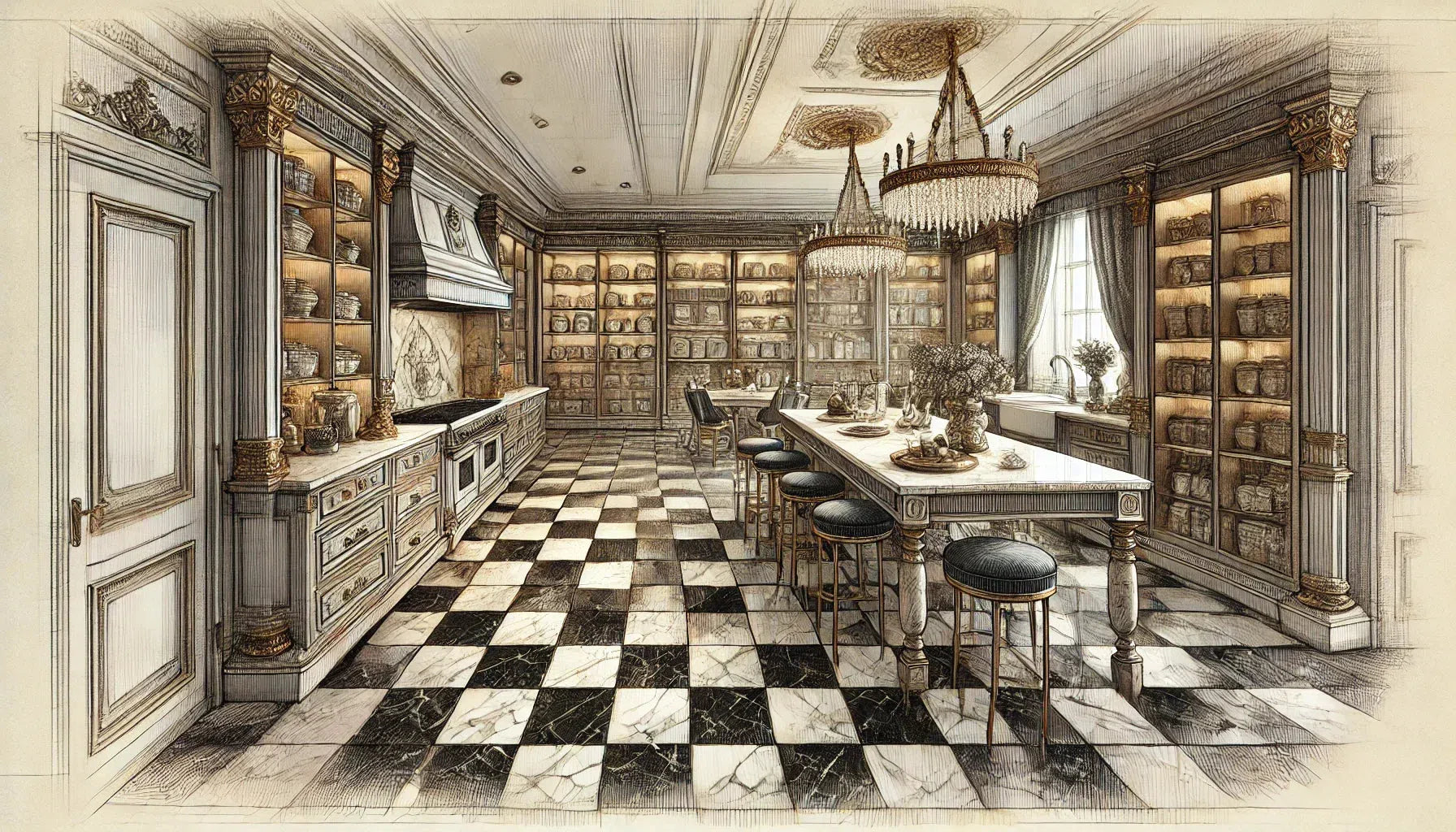

Polishing is an art form in itself, using brushes, rubber, and diamond tools. Each type of marble – white, black, red, green – requires a specific polishing technique to bring out its natural beauty. Finally, the polished slabs are cut to the exact shape needed for their intended purpose, whether they are thin tiles or larger decorative pieces.

Global Projects and Artistic Collaborations

ENRO's marble graces impressive projects worldwide, including mosques in Abu Dhabi and corporate headquarters in the United States. They also create luxurious floor coverings that transform spaces. In the final stages, skilled artisans assemble the pieces, carefully matching color patterns to ensure a flawless, aesthetically pleasing final product.

A Legacy of Marble, A Vision for the Future

Paolo Carly, the head and owner of the 200-year-old company, isn't worried about depleting the marble mountains. He explains that the reserves are vast, measured in thousands of years, and their extraction is a minimal part of the total resource. White statuario marble remains the company's core business, but they are also embracing the future. They've invested in 3D technology to create intricate art sculptures, merging their traditional craftsmanship with modern robotics. This innovative spirit is further showcased through collaborations with renowned artists like Hans Arp, Henry Moore, and Tony Cragg. These partnerships help develop their technology and integrate architectural design and art into their daily fabrication processes.

To nurture the next generation of artisans, ENRO partners with a local vocational school. Students work on projects, like an eye inspired by Michelangelo's David, connecting them to the region's rich artistic heritage. The miners, though still working high on the mountain, are steadily bringing down these blocks of timeless beauty, one piece at a time.

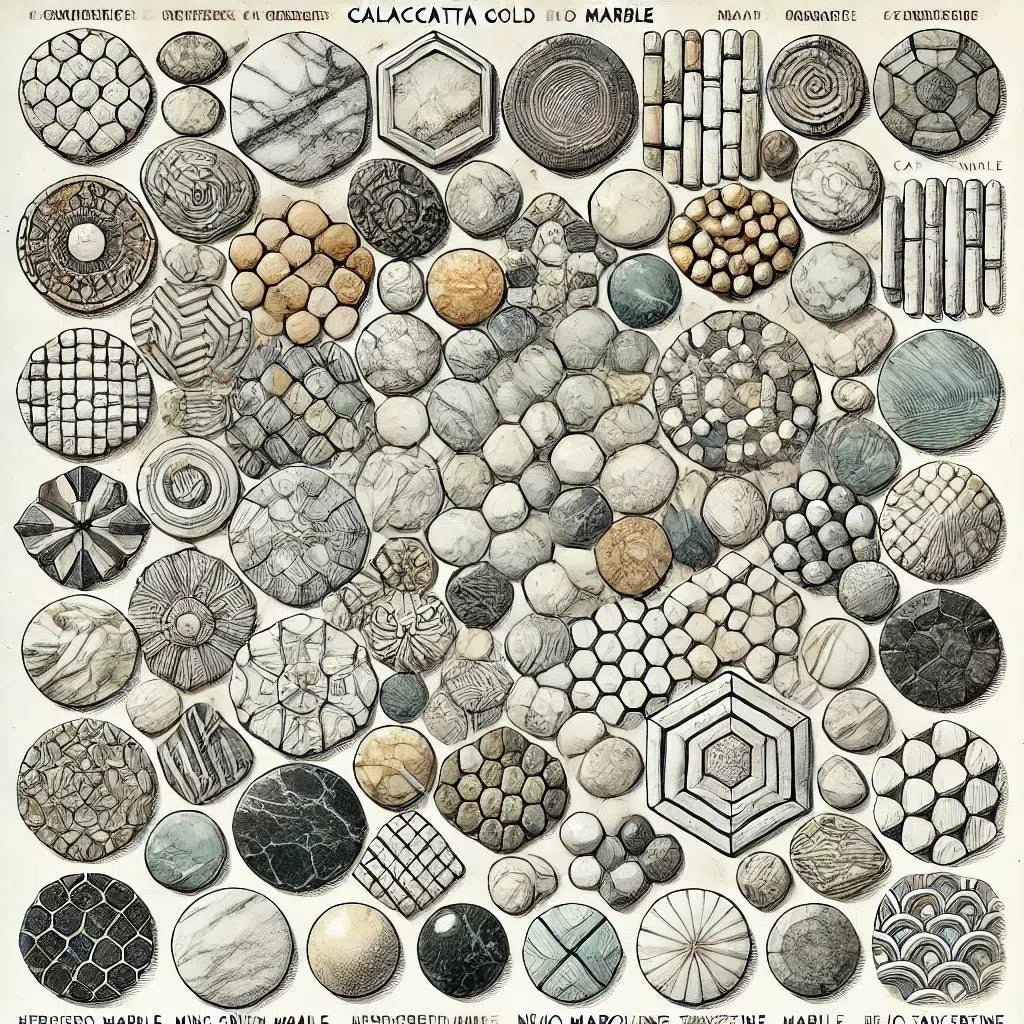

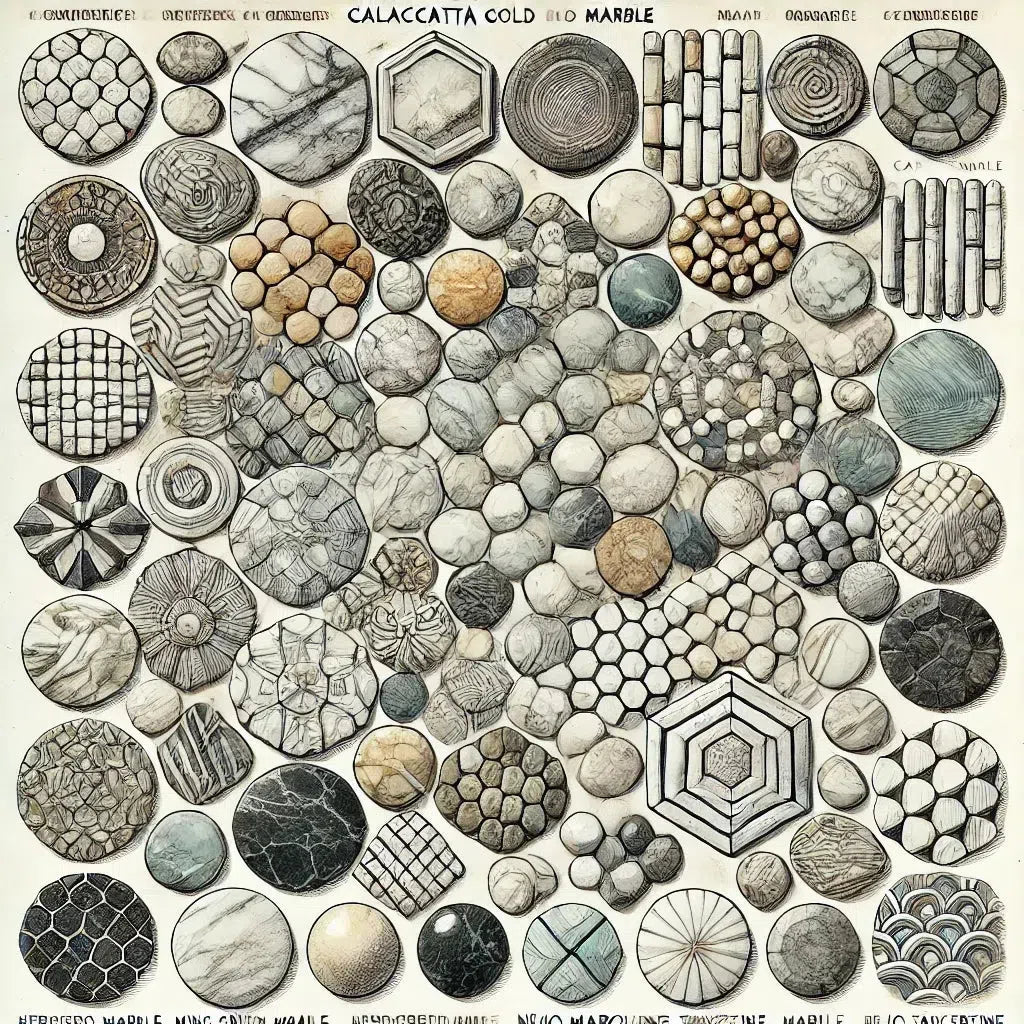

Best Selling Marble Collections

Best Selling Marble Collections

Arabescato Corchia

Arabescato Corchia Bardiglio

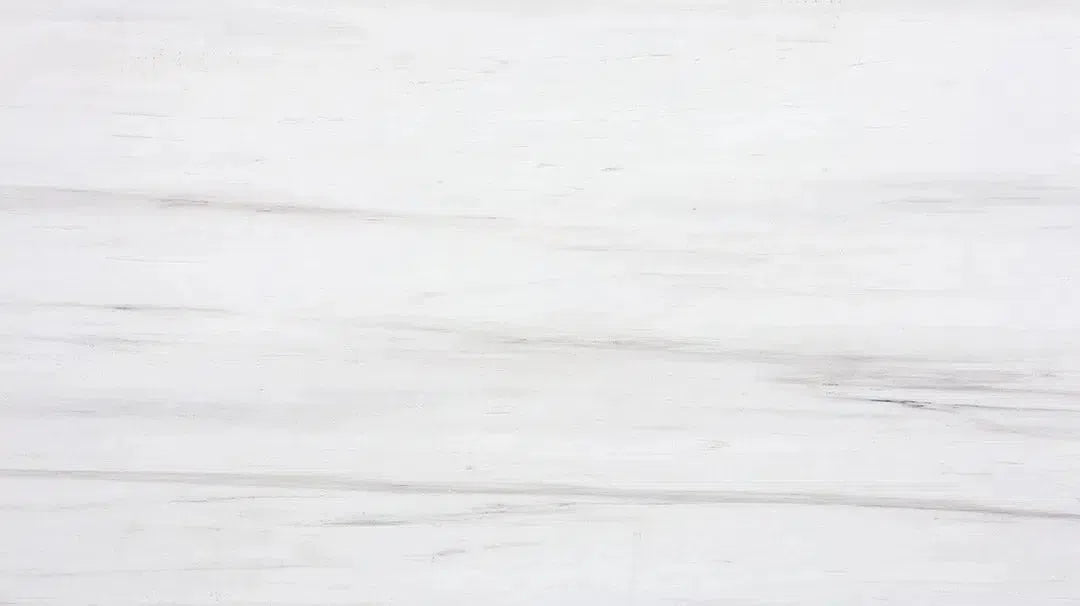

Bardiglio Bianco Dolomite

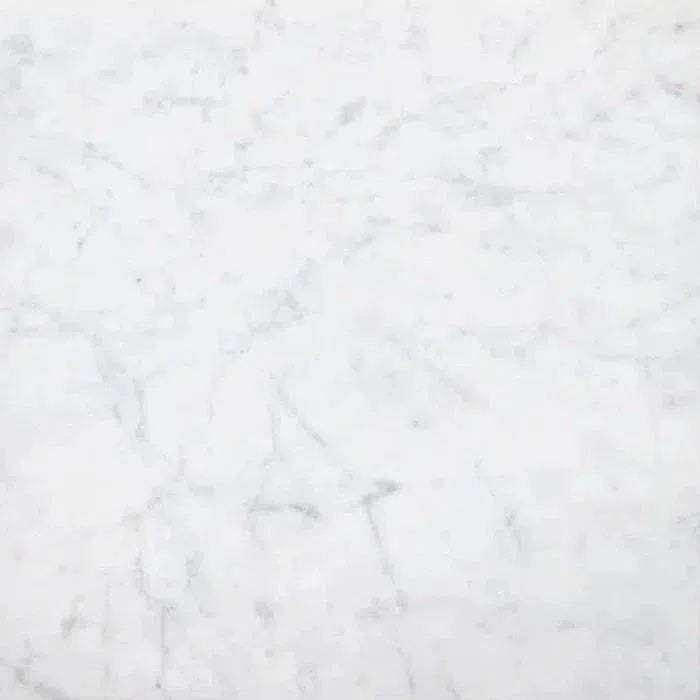

Bianco Dolomite  Carrara White

Carrara White  Calacatta Gold

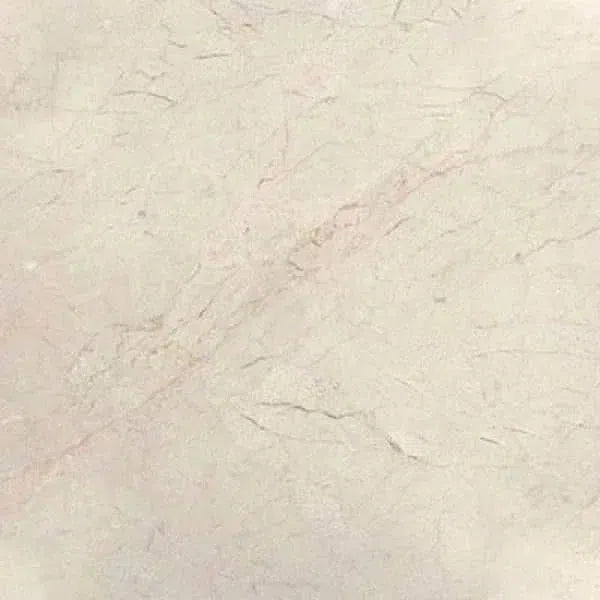

Calacatta Gold Crema Marfil

Crema Marfil Custom Made Mosaic

Custom Made Mosaic Emperador Dark

Emperador Dark Nero Marquina

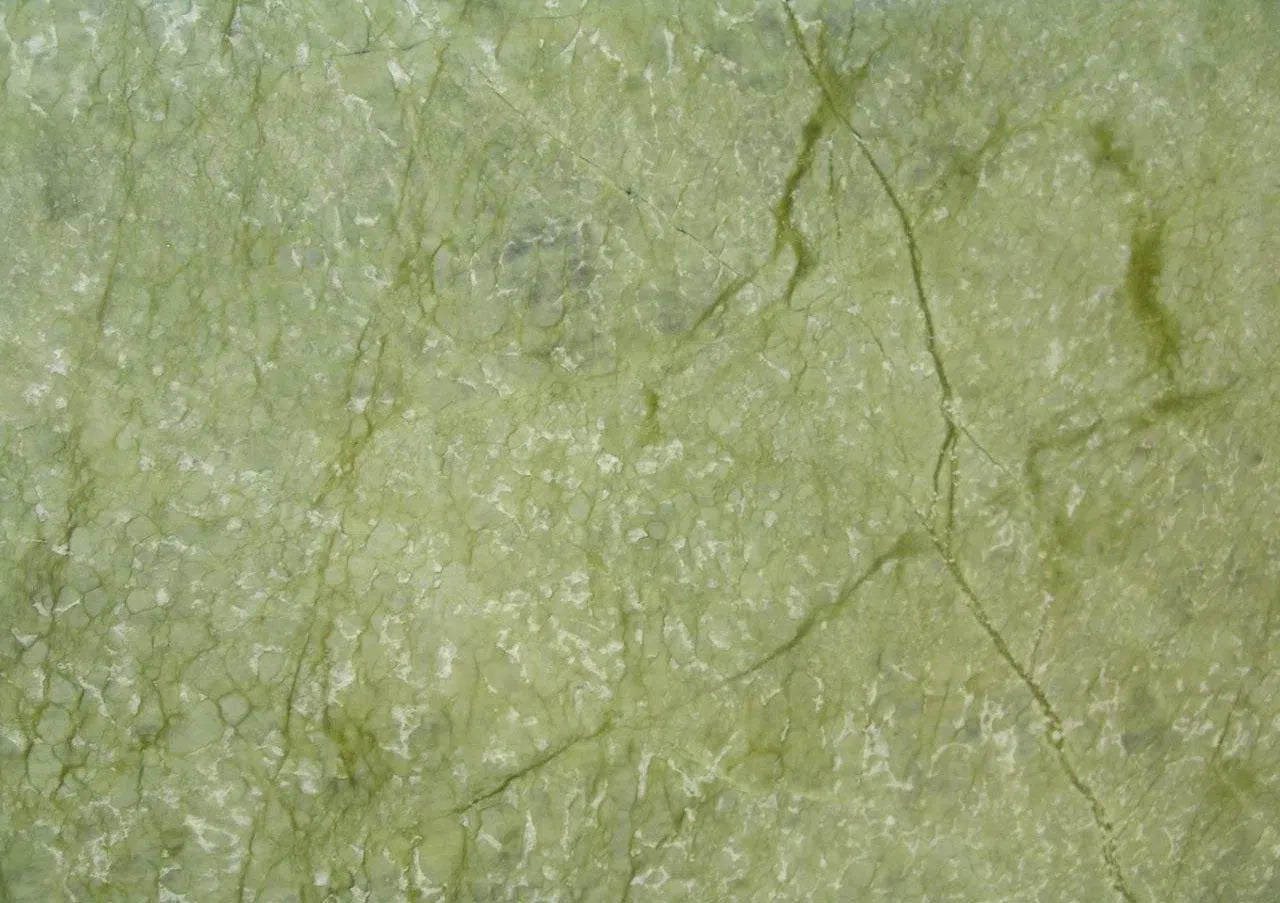

Nero Marquina Ming Green Marble

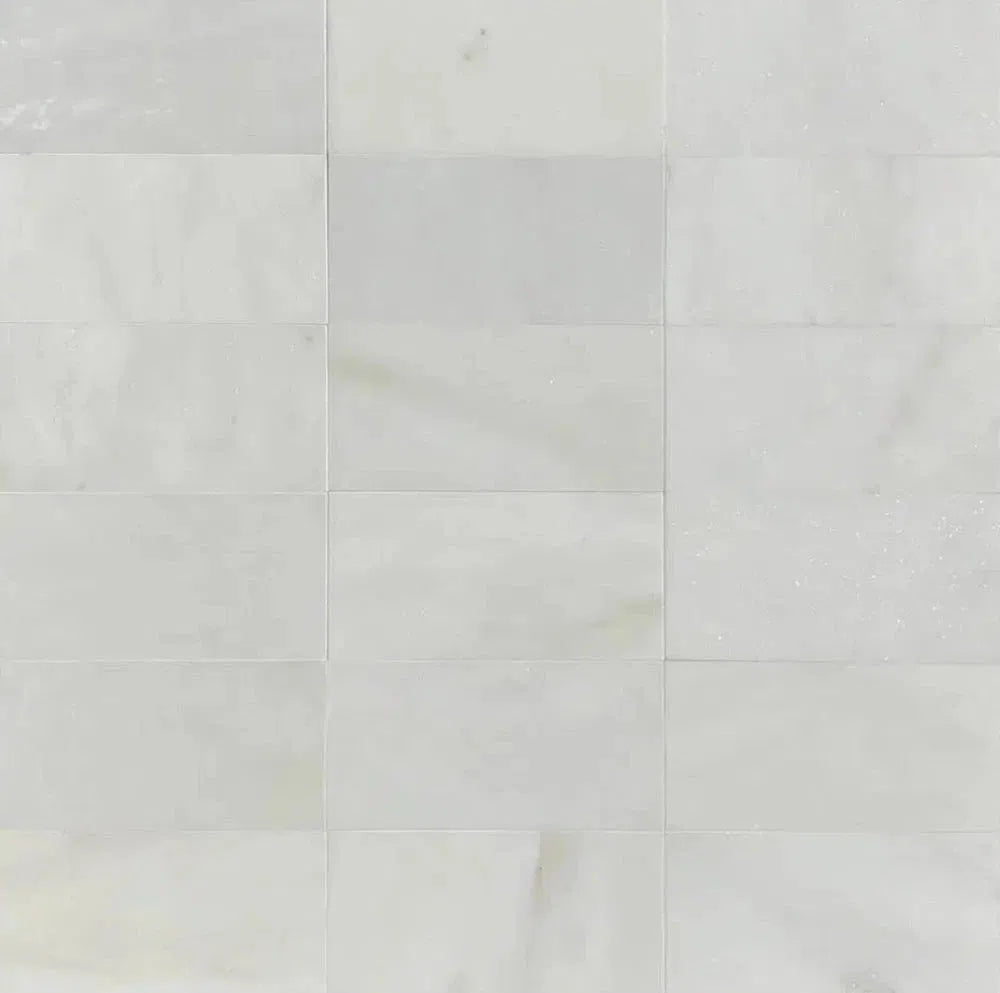

Ming Green Marble Oriental White Marble (Asian Statuary Marble)

Oriental White Marble (Asian Statuary Marble) Statuary - Statuario White (Italian) Marble

Statuary - Statuario White (Italian) Marble Thassos White

Thassos White White Pearl/Botticino Beige Marble

White Pearl/Botticino Beige Marble Best Selling Travertine Collections

Best Selling Travertine Collections

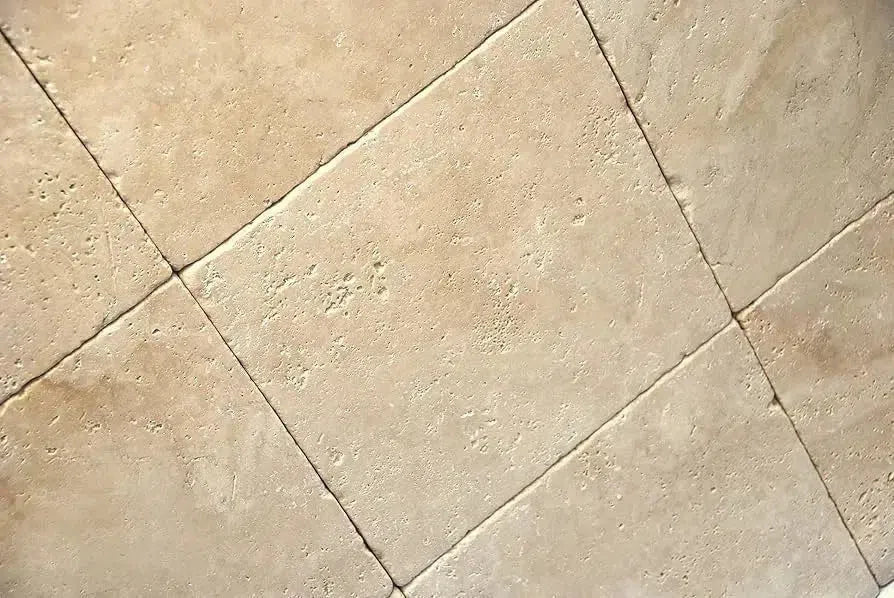

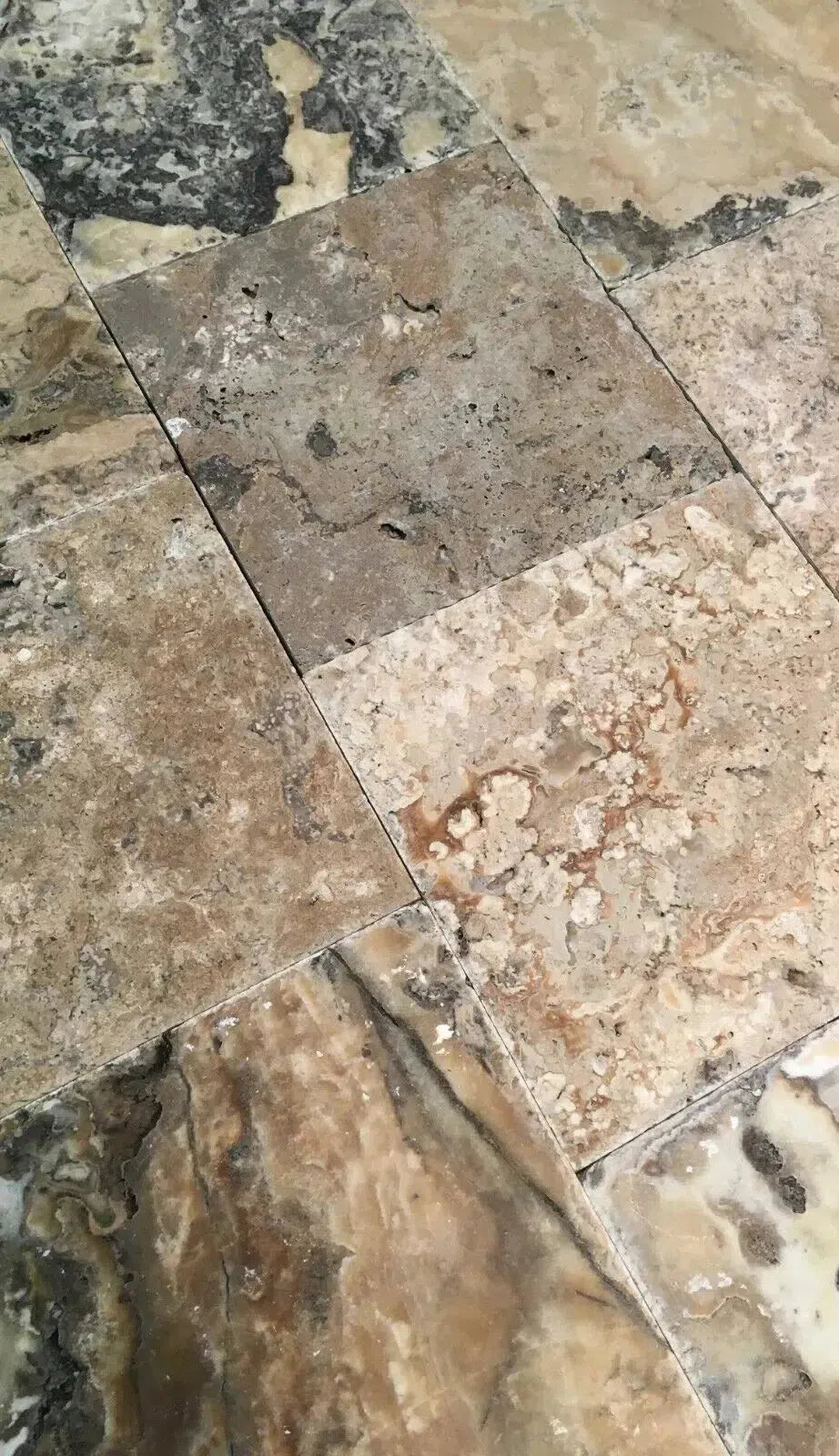

Ivory Travertine

Ivory Travertine Noce Travertine

Noce Travertine Exotic Noce Travertine

Exotic Noce Travertine Scabos | Autumn Leaves Travertine

Scabos | Autumn Leaves Travertine Silver Travertine

Silver Travertine Exotic Travertine

Exotic Travertine Checkerboard

Checkerboard

Patterned Tile

Patterned Tile

Shop By Material

Shop By Material

Travertine

Travertine Marble

Marble Limestone

Limestone Soap Stone

Soap Stone Quartz

Quartz Granite

Granite Shop By Name

Shop By Name

Absolute Black Granite

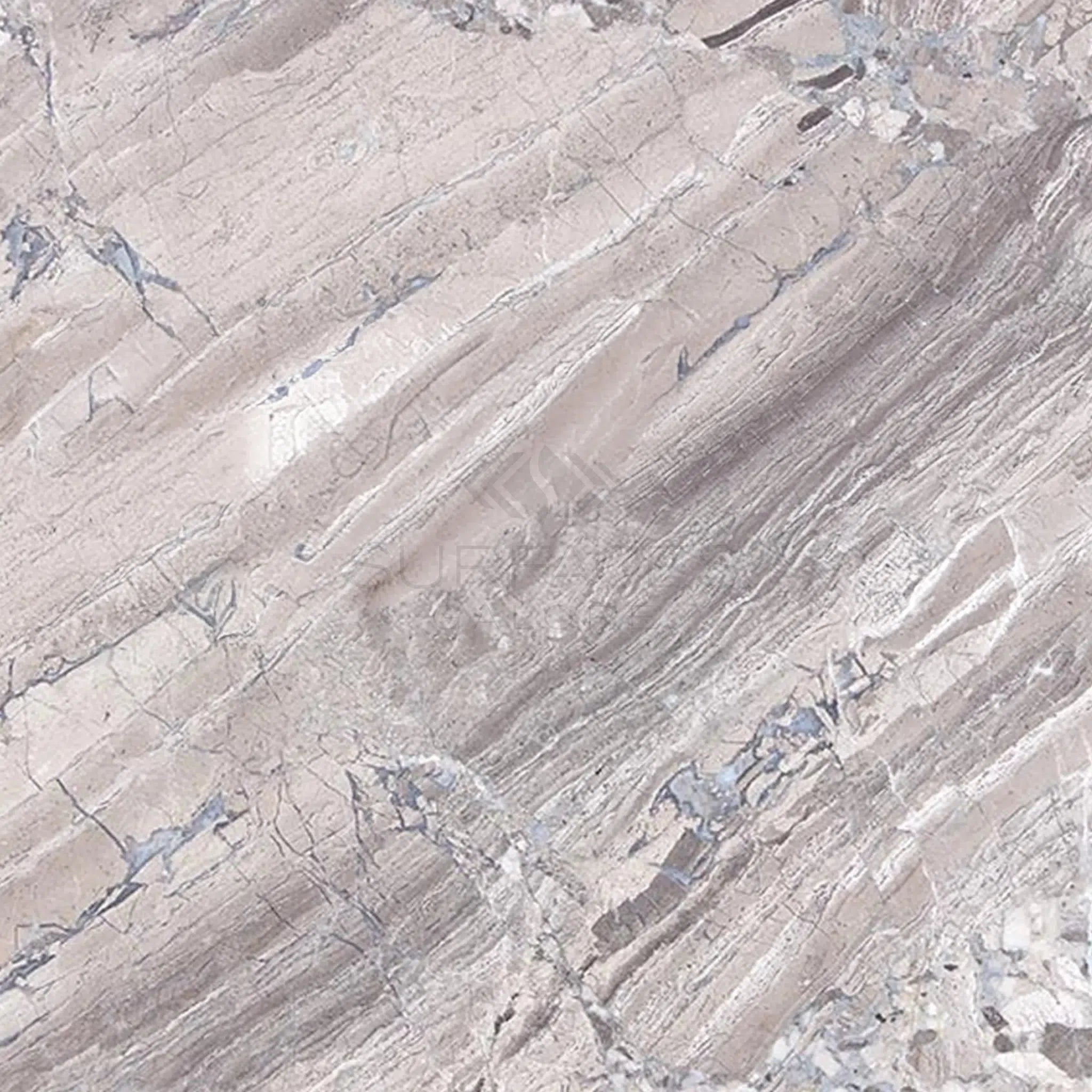

Absolute Black Granite Atlantic Gray Marble

Atlantic Gray Marble Antico Onyx Travertine

Antico Onyx Travertine Bianco Congelato Dolomite

Bianco Congelato Dolomite Bianco Venatino (Bianco Mare) Marble

Bianco Venatino (Bianco Mare) Marble Burgundy Mocha Marble

Burgundy Mocha Marble Calacatta Verde Royale Marble

Calacatta Verde Royale Marble Cappuccino Marble

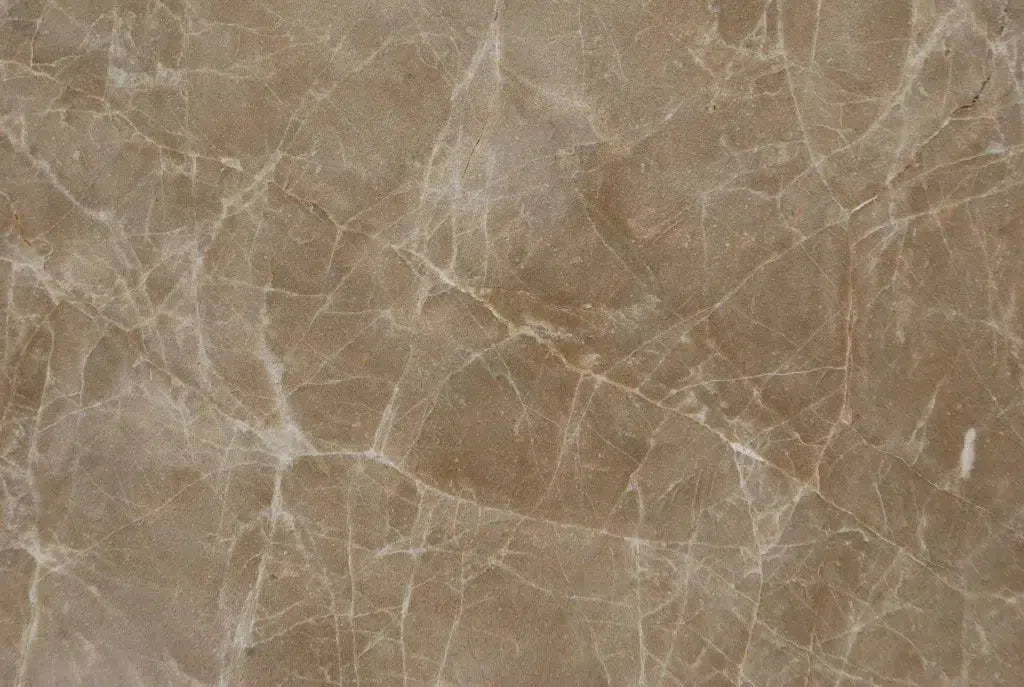

Cappuccino Marble Diano Royal (Queen Beige) Marble

Diano Royal (Queen Beige) Marble Durango Cream Traverine

Durango Cream Traverine Emperador Light Marble

Emperador Light Marble Empress Green Marble

Empress Green Marble Gold/Yellow Travertine

Gold/Yellow Travertine Golden Horizon Marble

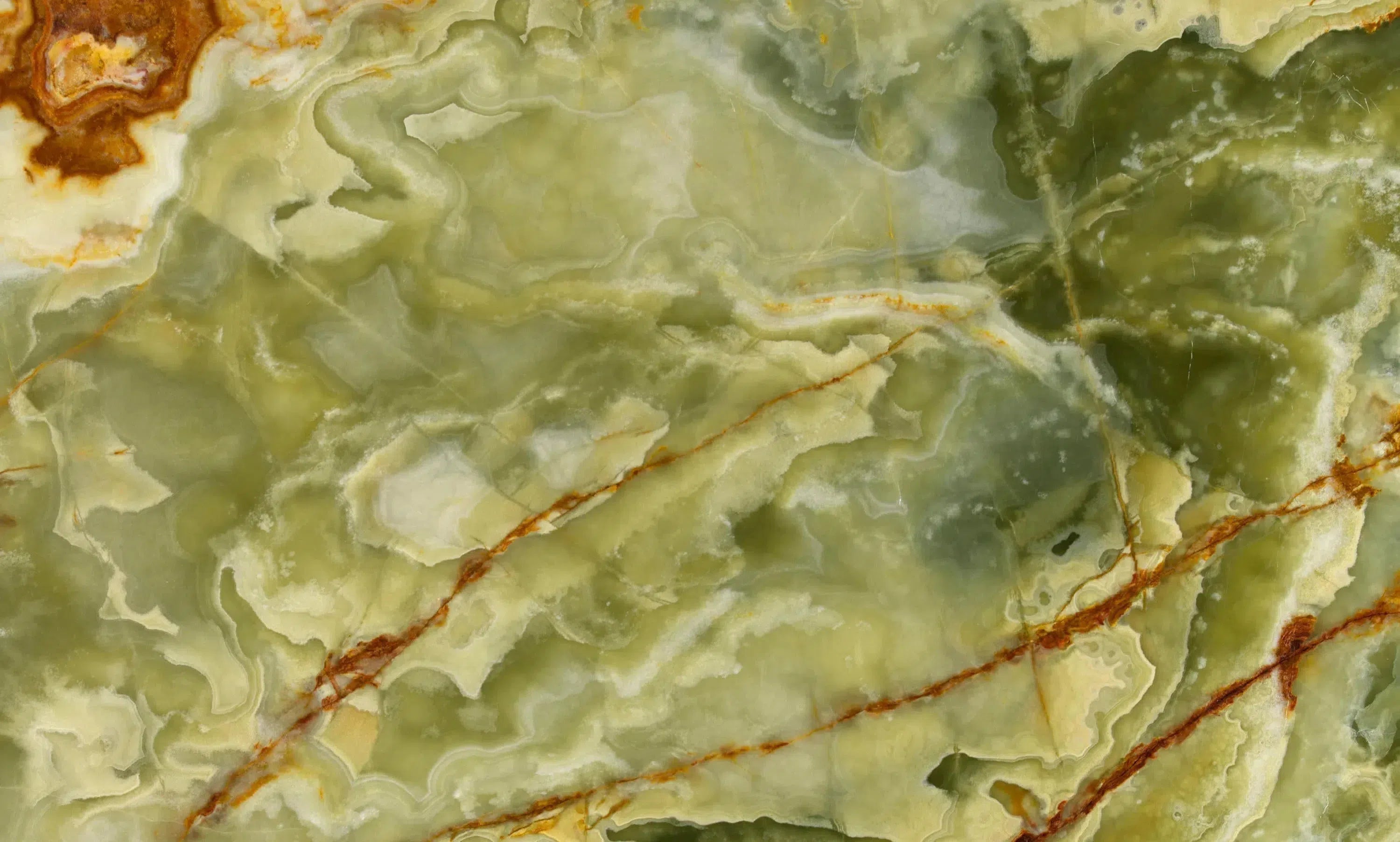

Golden Horizon Marble Green Onyx Marble

Green Onyx Marble Haisa Light (White Wood) Limestone

Haisa Light (White Wood) Limestone Honey Onyx Marble

Honey Onyx Marble La Travonya Travertine

La Travonya Travertine Malibu Travertine

Malibu Travertine Mink (Equator) Marble

Mink (Equator) Marble Mixed (Ivory-Noce-Gold) Travertine

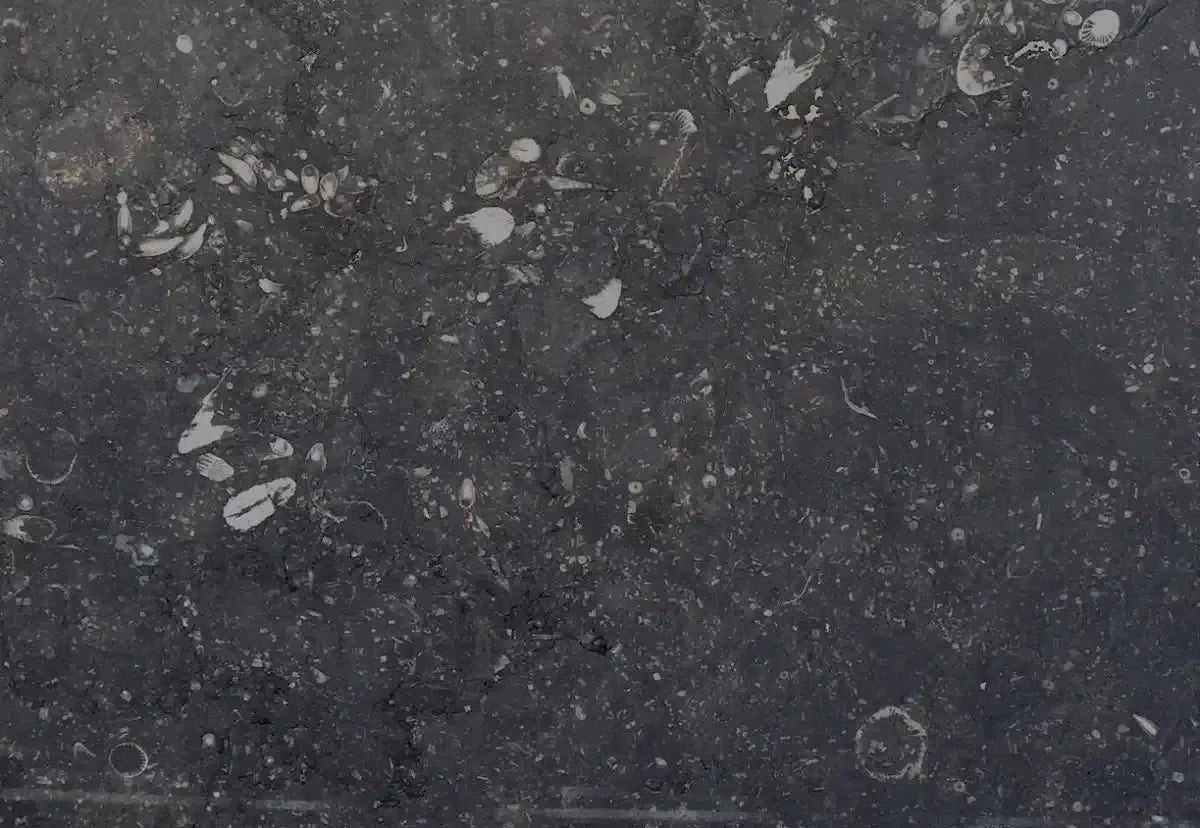

Mixed (Ivory-Noce-Gold) Travertine Pierre Bleue (Pierre Blue) Marble

Pierre Bleue (Pierre Blue) Marble Philadelphia Travertine

Philadelphia Travertine Rosé Aurora Marble

Rosé Aurora Marble Rosetta Storm Marble

Rosetta Storm Marble Rosso Levanto Marble

Rosso Levanto Marble Rojo Alicante Marble

Rojo Alicante Marble Sahara Ember Marble

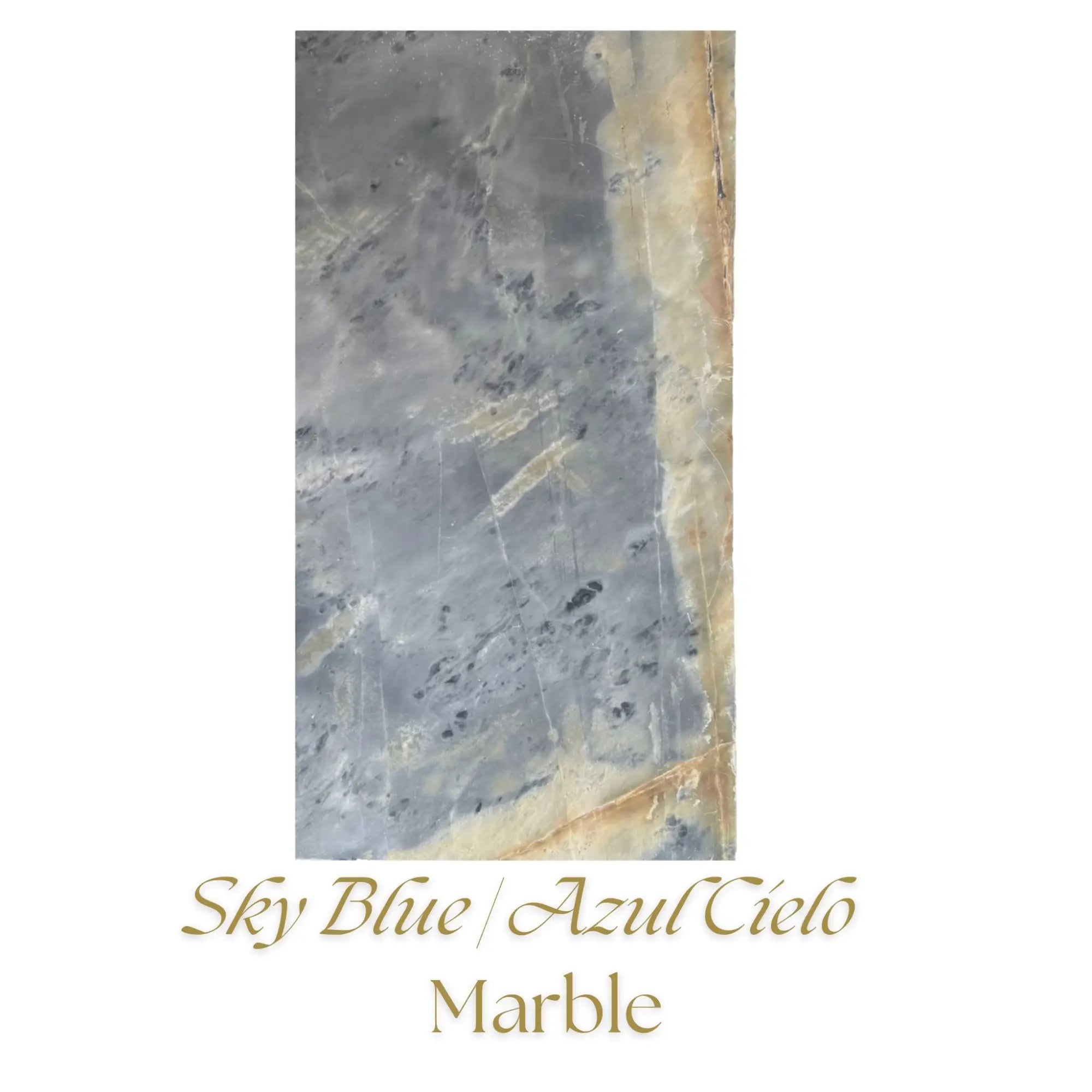

Sahara Ember Marble Sky Blue | Azul Cielo Marble

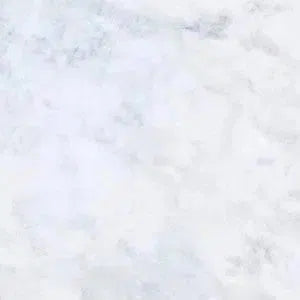

Sky Blue | Azul Cielo Marble Snow White (Afyon White) Marble

Snow White (Afyon White) Marble Spanish Mix Marble

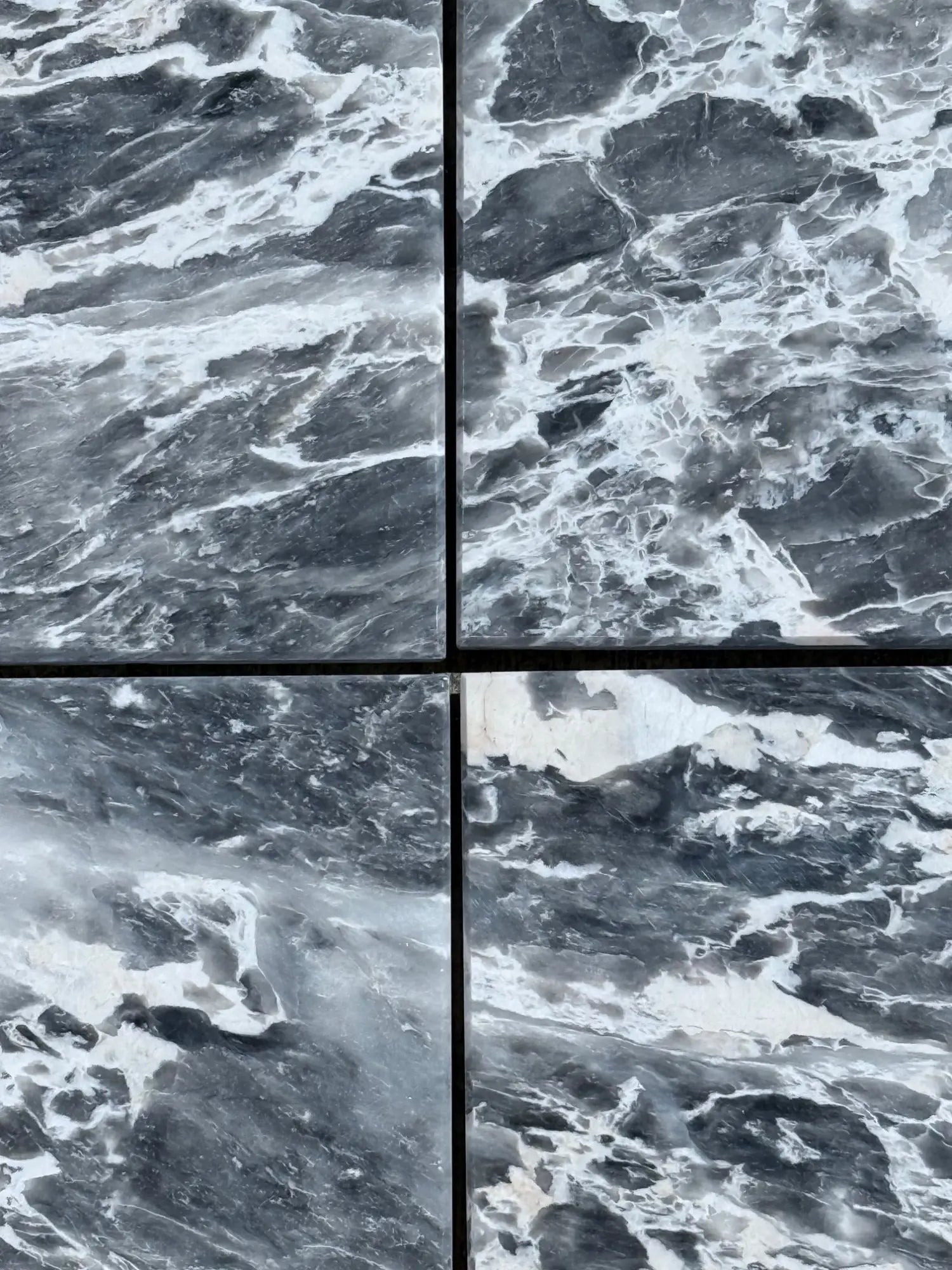

Spanish Mix Marble Storm Gray Marble

Storm Gray Marble Tundra Gray (Atlantic Gray) Marble

Tundra Gray (Atlantic Gray) Marble Valencia Travertine

Valencia Travertine Valerenga Travertine

Valerenga Travertine Walnut Travertine

Walnut Travertine White Onyx Marble

White Onyx Marble Shop By Type

Shop By Type

Marble Tiles

Marble Tiles Marble Mosaic

Marble Mosaic Travertine Tiles

Travertine Tiles Travertine Mosaic

Travertine Mosaic 4 pcs Versailles Pattern / French Pattern Set

4 pcs Versailles Pattern / French Pattern Set Molding/Trim

Molding/Trim Border/Listello

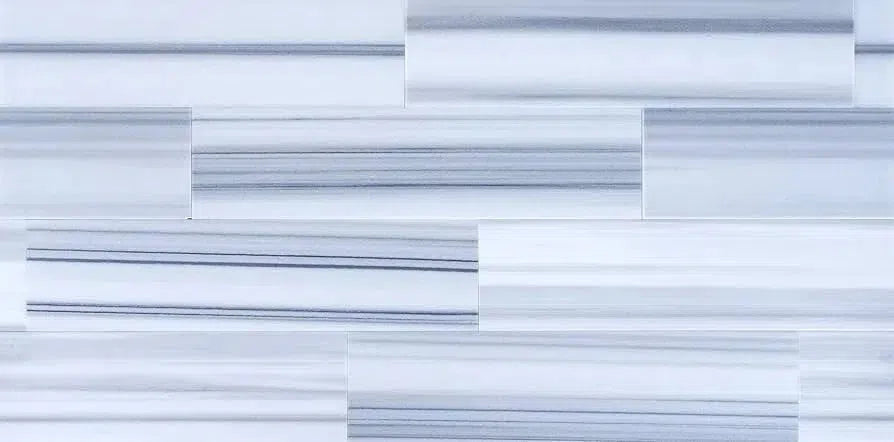

Border/Listello Ledger-Panel

Ledger-Panel Checkerboard

Checkerboard Patterned Tile Collection

Patterned Tile Collection  Shop By Finish

Shop By Finish

Polished

Polished Honed

Honed Brushed

Brushed Split Face

Split Face Textured

Textured Tumbled

Tumbled Accessories

Accessories

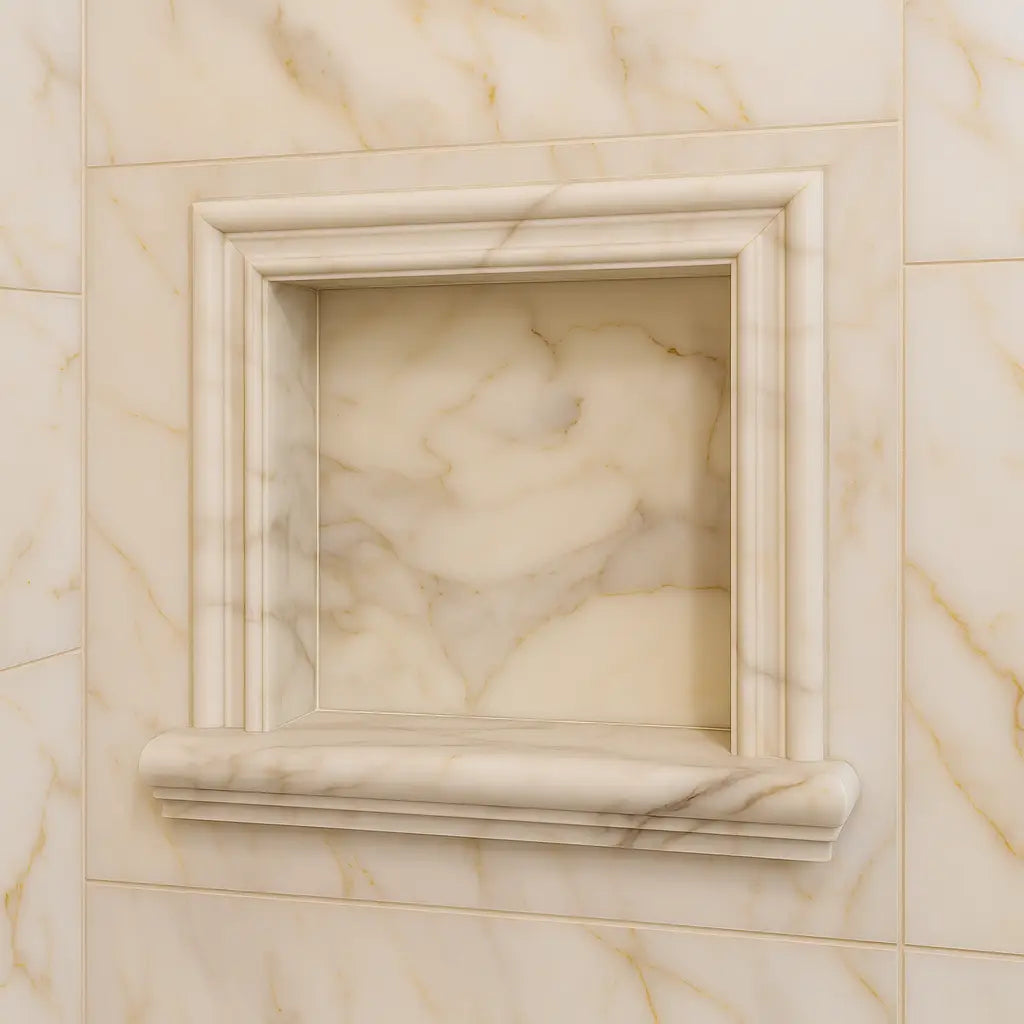

Wall Plate / Switch Plate

Wall Plate / Switch Plate Shampoo Niche

Shampoo Niche Corner Shelf

Corner Shelf Clearance

Clearance

Leave a comment