Why Calacatta Marble Is So Expensive

Calacatta marble, a material prized for its beauty and used by artists for centuries, is one of the most expensive marbles available. Even though it's mined in the same mountains as Carrara marble, Calacatta can cost more than double. This difference in price is largely due to its rarity and unique characteristics.

What Makes Calacatta Marble So Special?

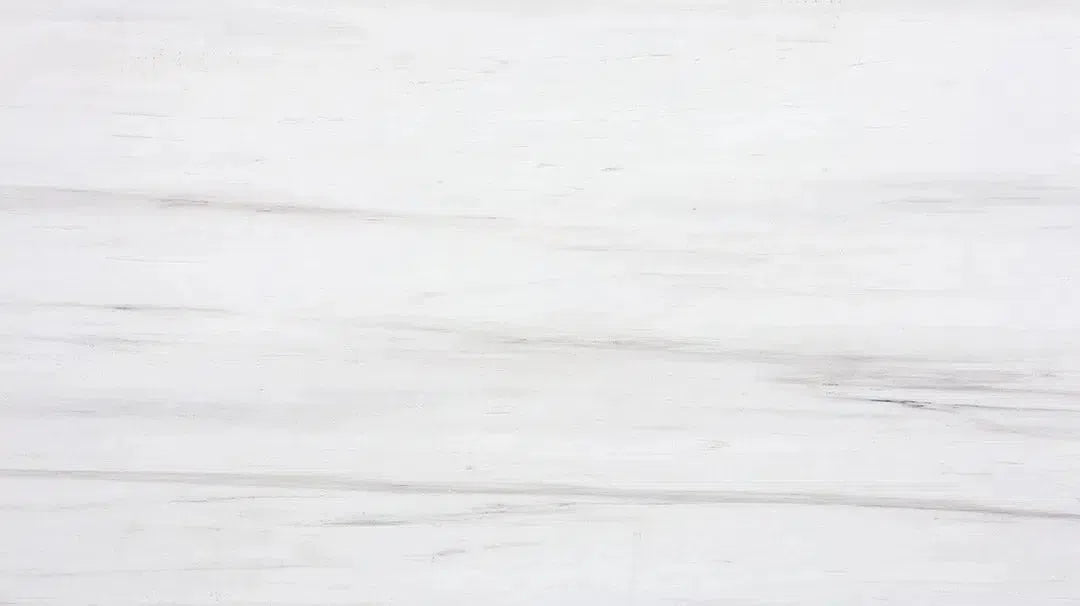

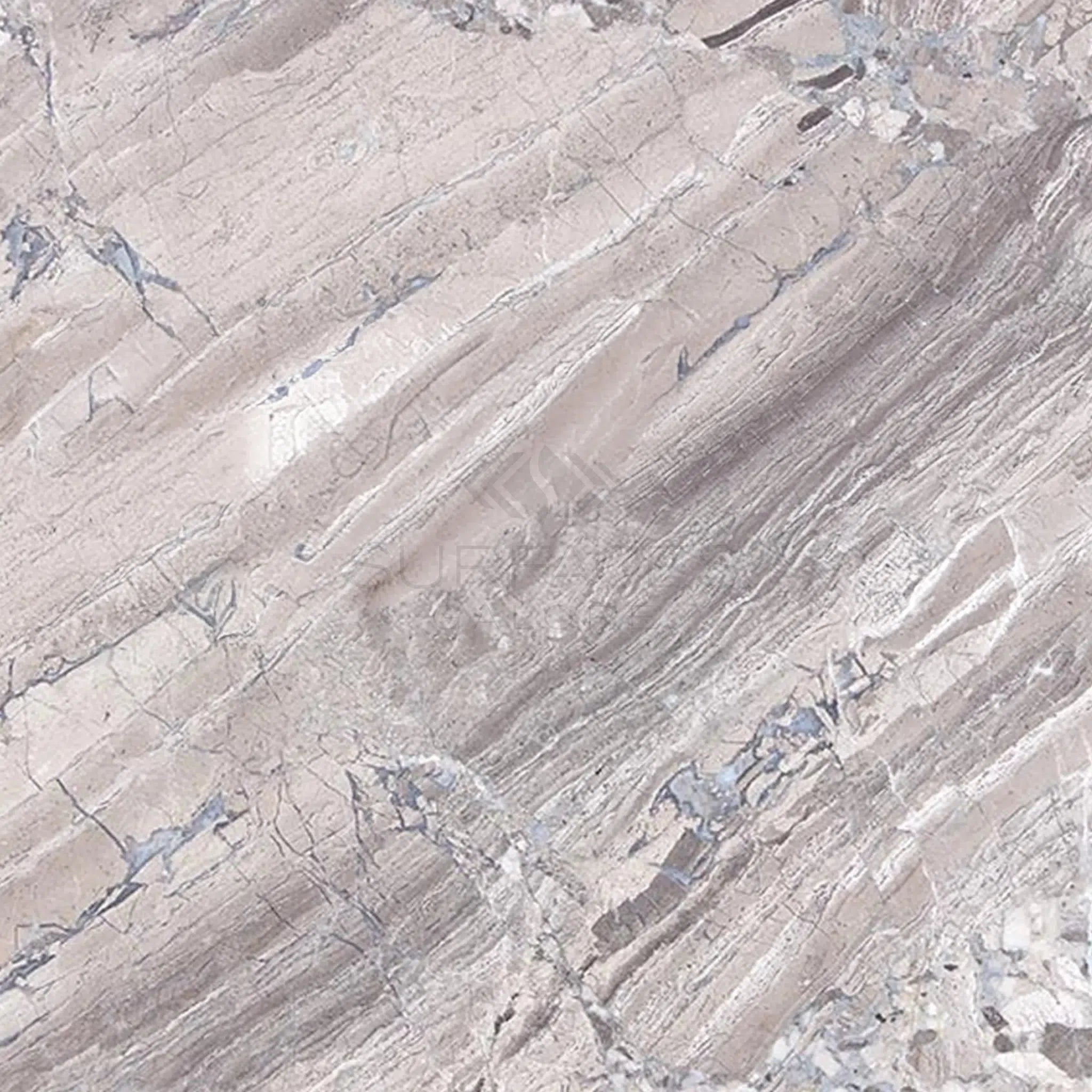

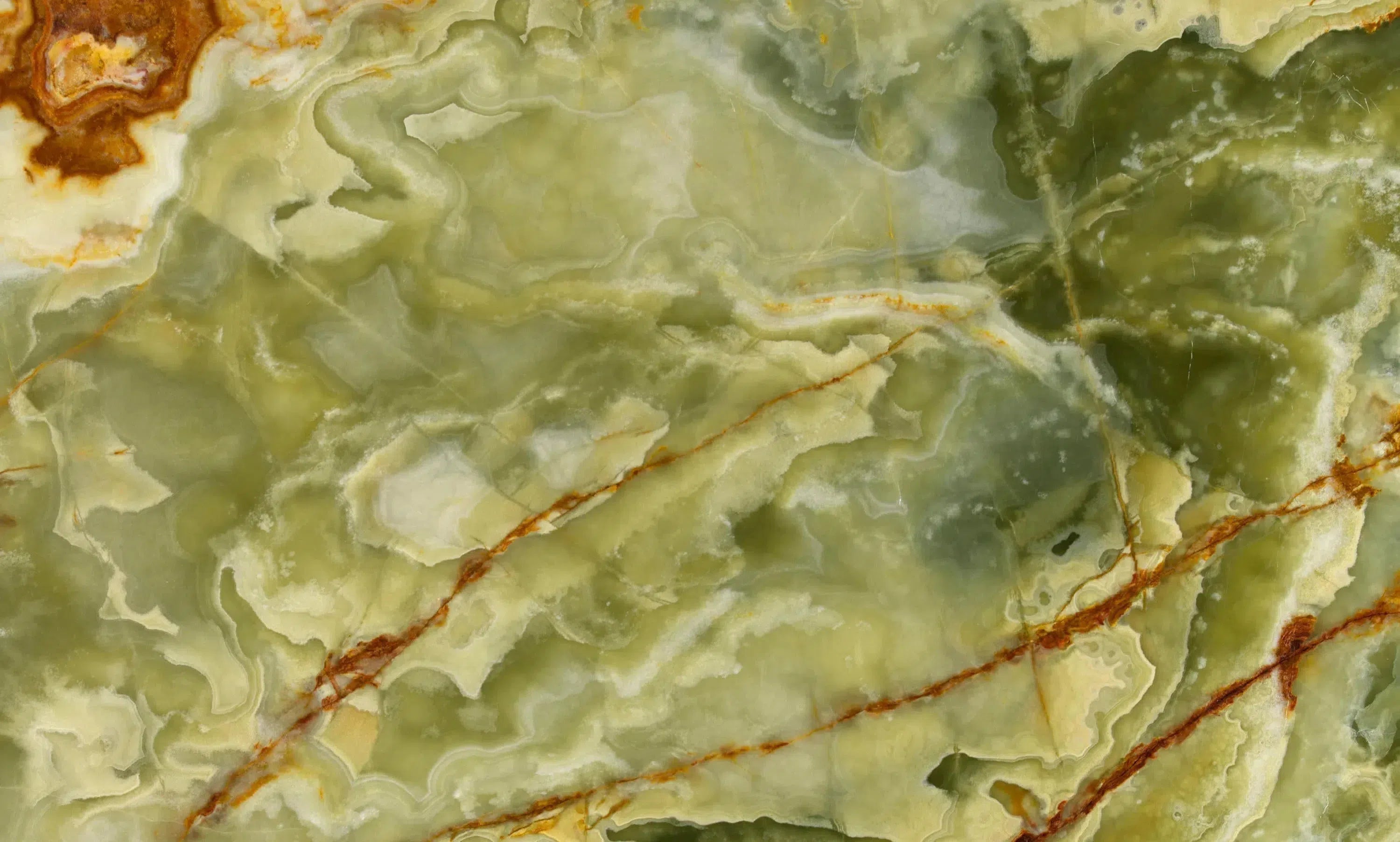

Calacatta marble stands out with its warm, ivory-white background, often highlighted by thick, distinctive gold or gray veins. This unique look sets it apart from other marbles. While Carrara marble is also quarried in the Apuan Alps of Carrara, Italy, Calacatta is found in a much more limited area. This scarcity is the primary reason for its high price point.

The Mining Process: Precision and Experience

Extracting Calacatta marble is a challenging process that requires immense skill and experience. Miners like Enrico, who has been working in the quarries for 40 years, must have a keen eye and work with great precision. They need to carefully navigate the mountain's natural defects to avoid damaging the marble during extraction. These flaws dictate where miners can cut and how much marble they can retrieve, directly impacting its final sale price.

Key Takeaways from the Mining Process:

- Miners need decades of experience to extract Calacatta marble successfully.

- Working around natural flaws in the mountain is critical to prevent the marble from breaking.

- The location and presence of defects influence the quantity and quality of the marble extracted.

The extraction itself involves drilling strategic holes and using diamond-braided cords to cut the marble into large blocks. Chainsaws, kept wet to protect the stone, help detach these blocks. An average block can be quite large, measuring 12 cubic meters and weighing around 36 metric tons. Once detached, these heavy blocks are transported to processing facilities.

Processing Calacatta Marble: From Block to Slab

At the processing facility, the Calacatta marble blocks are carefully sliced into slabs. This stage is just as critical as mining, as any mistake can ruin the valuable stone. Slabs as thin as two centimeters are cut using saws with over 100 thin blades. The machinery is kept wet throughout this process.

After cutting, the slabs undergo further preparation. They are sanded and pre-smoothed. Then, a process called "resination" takes place. This involves applying resin to fill any existing cracks or holes in the slab. Resin is also used to repair pieces that may have broken during the quarrying process. For a rare material like Calacatta, even a small error here can significantly affect the slab's quality and price. Once the resin is evenly applied, it's dried under UV light to ensure the slab is flawless.

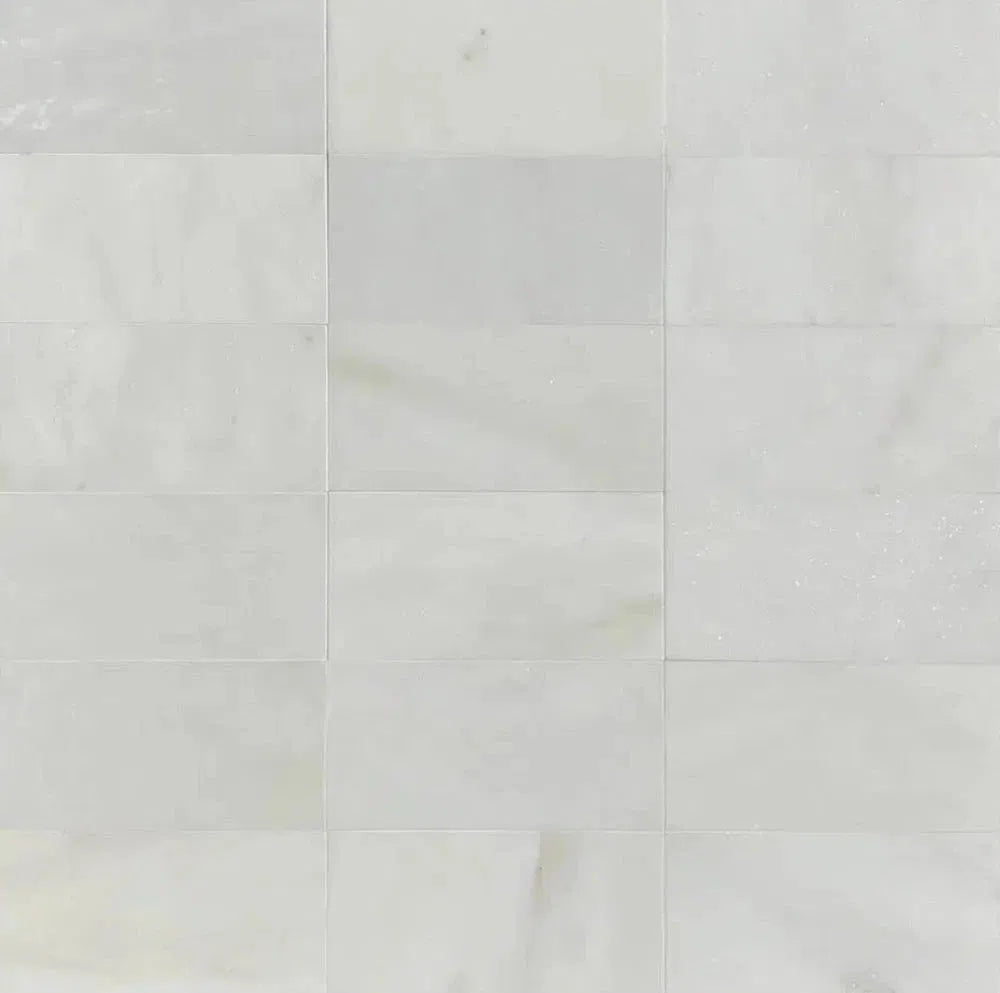

Finally, the Calacatta slabs are honed and polished until they achieve a sparkling finish, making them visually appealing.

Customization and Client Collaboration

Calacatta marble is typically processed on a per-order basis. Producers work closely with customers throughout the entire process, ensuring the final product is perfectly customized to their needs. Because once the marble is fully processed, there's no turning back.

Why the High Demand?

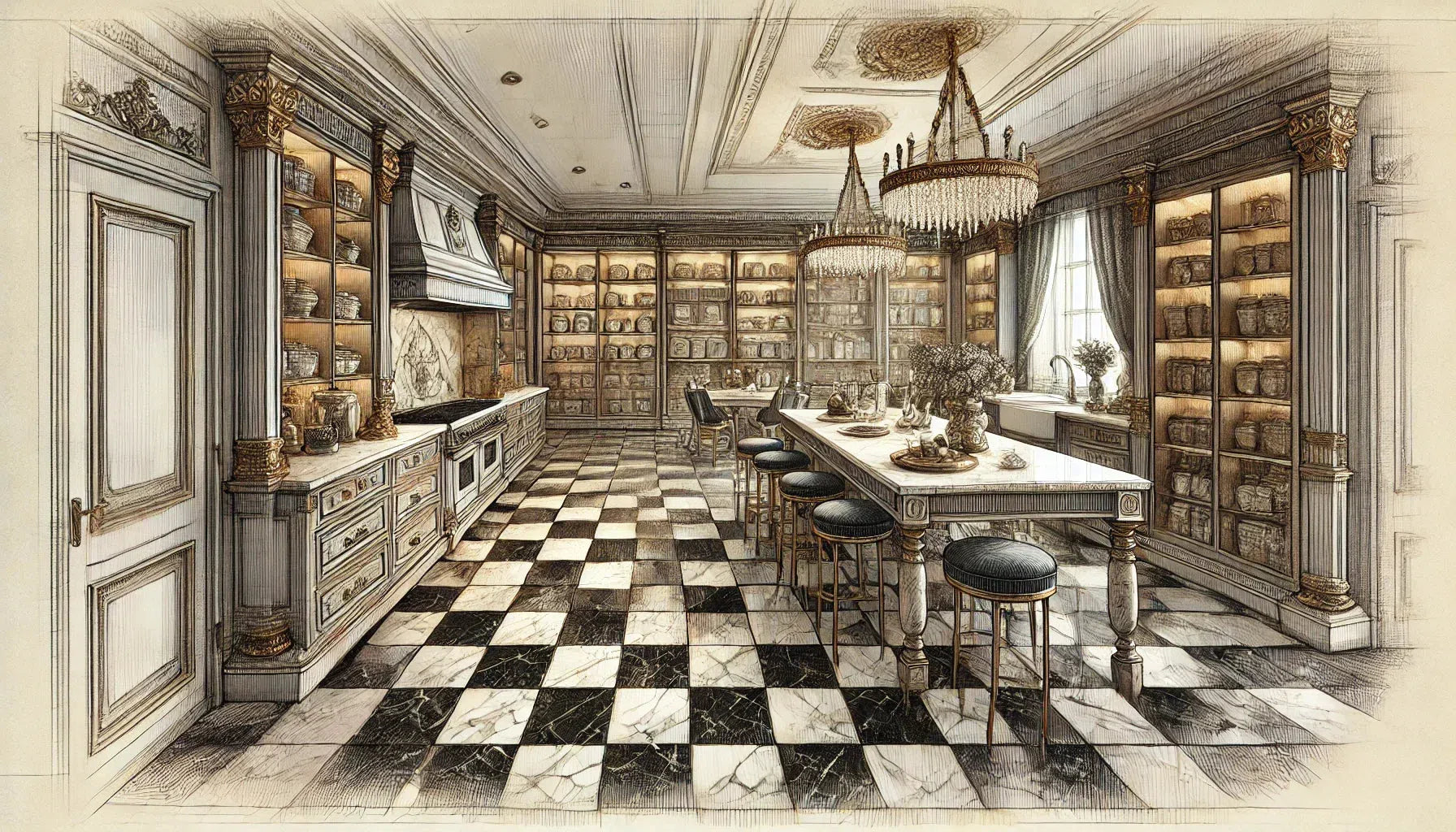

Despite the risks and high costs, the demand for Calacatta marble remains strong. Customers often choose it for its luxurious, high-end appeal, recognizing it as a timeless and classic material that complements various design styles. White marbles, including Calacatta, are generally preferred because they tend to have fewer flaws than darker marbles, requiring less maintenance and fewer repairs.

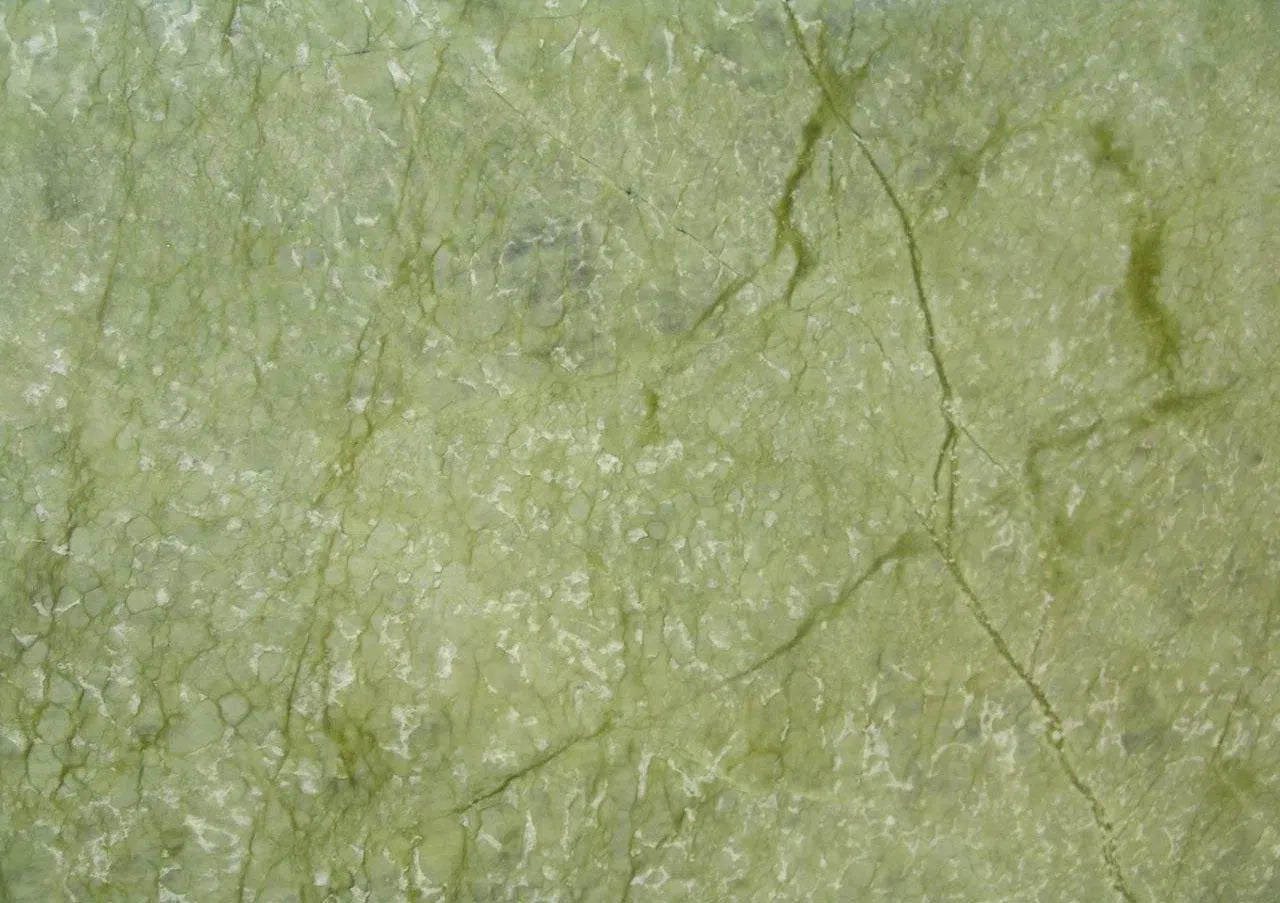

Calacatta is even more sought after than other white marbles like Carrara. Its veins appear crisper and less faded, and the generally fewer veins make it easier to incorporate into interior and exterior designs. It also offers a softer contrast compared to other high-end marbles like Statuario, which has a milky background with darker gray veining.

Variations in Calacatta Marble:

- Standard Calacatta: Can cost over $10,000 per slab.

- Calacatta Gold: Characterized by gold-colored veins, this variation is even rarer and can cost more than $29,000 per slab.

- Serene Calacatta: This specific type is even more expensive.

While exact pricing is often kept private within the industry, the demand for Calacatta has steadily increased over the past 40 years, even during economic downturns. This enduring desire for the material persists.

Environmental Concerns

However, the growing demand for Calacatta marble is not without its critics. In Carrara, locals and environmentalists have raised concerns about the impact of quarrying. The sawing and extraction methods have led to slurry and waste being carried into nearby environments through water runoff, affecting local groundwater. Environmentalists warn that the over-exploitation of the mountains could worsen these issues.

Despite these environmental challenges, the market for marble, and Calacatta in particular, continues to grow. The global marble market is projected to reach $68.5 billion by 2027, indicating that Calacatta will likely remain one of the world's most prized and expensive natural resources.

Best Selling Marble Collections

Best Selling Marble Collections

Arabescato Corchia

Arabescato Corchia Bardiglio

Bardiglio Bianco Dolomite

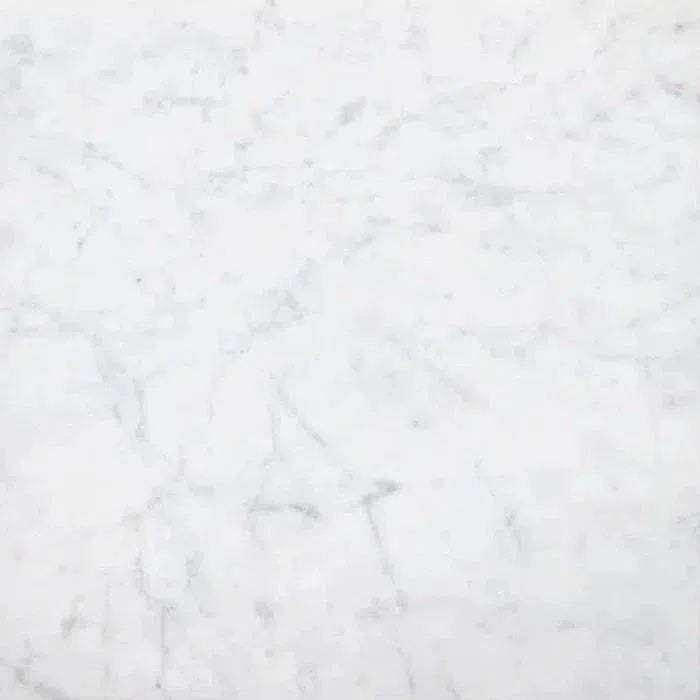

Bianco Dolomite  Carrara White

Carrara White  Calacatta Gold

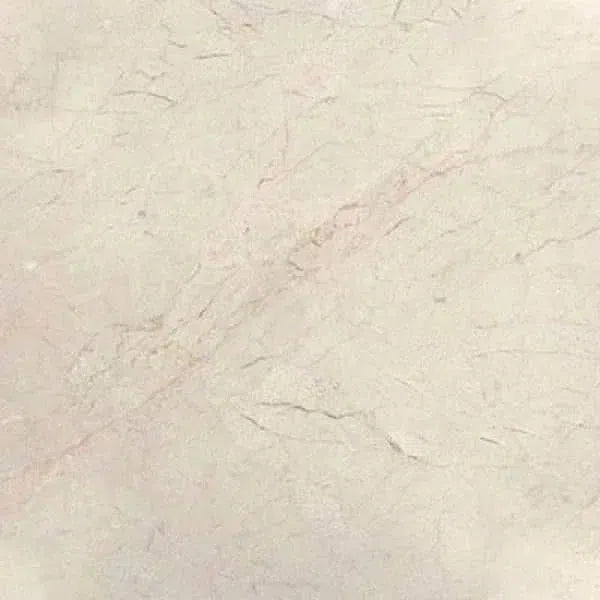

Calacatta Gold Crema Marfil

Crema Marfil Emperador Dark

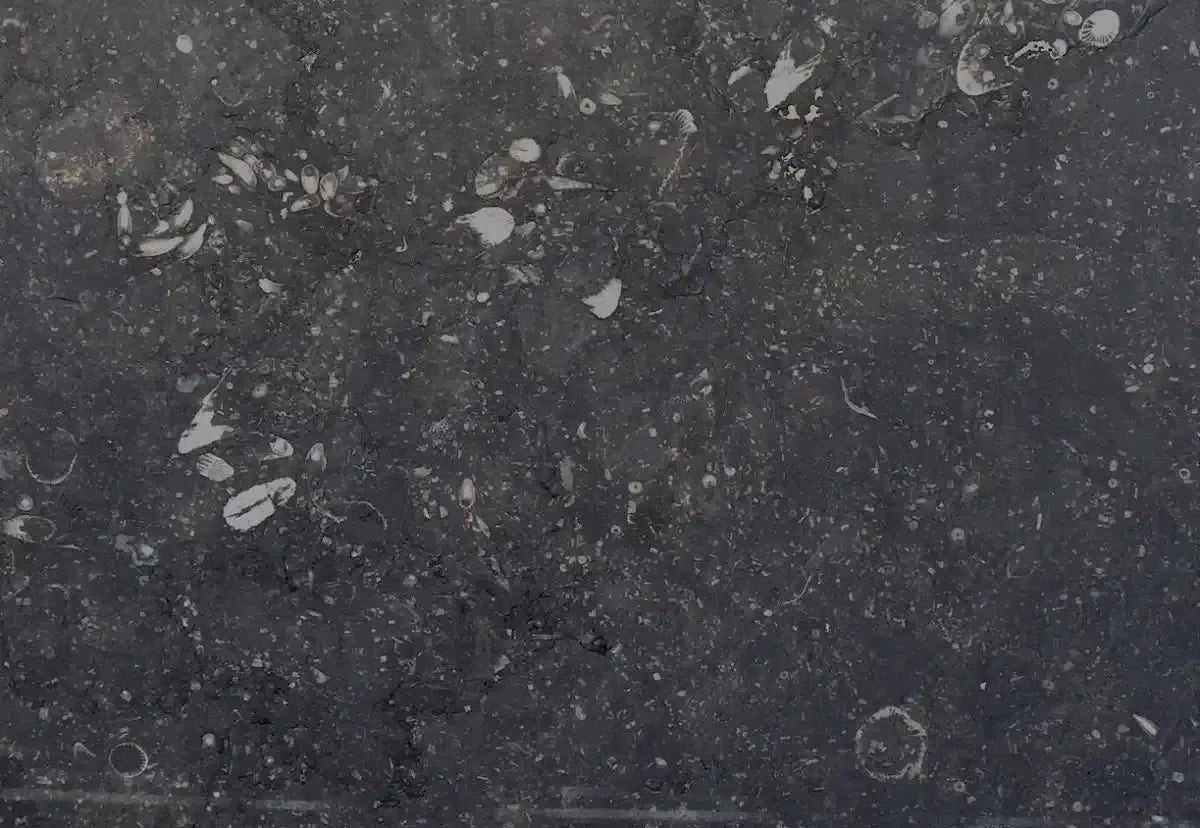

Emperador Dark Nero Marquina

Nero Marquina Statuary - Statuario White (Italian) Marble

Statuary - Statuario White (Italian) Marble Thassos White

Thassos White Best Selling Travertine Collections

Best Selling Travertine Collections

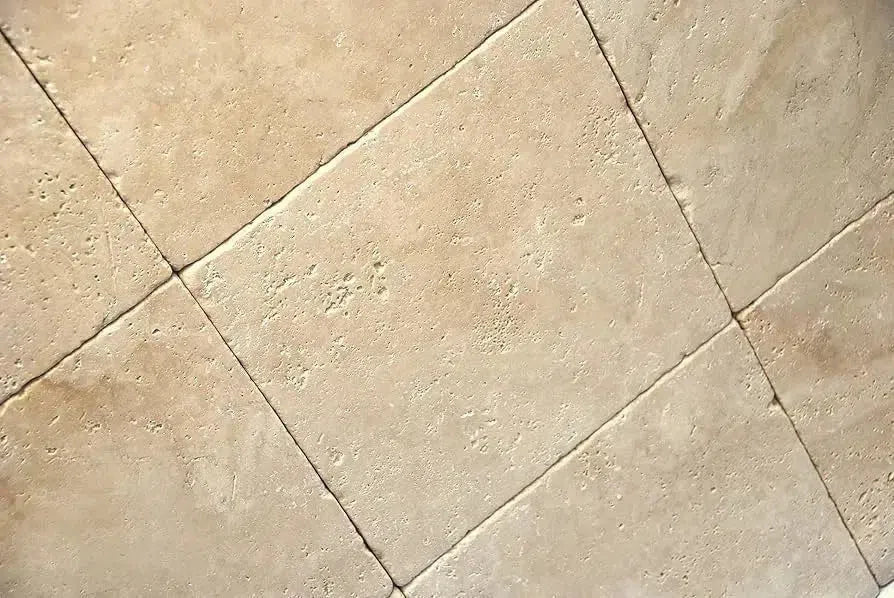

Ivory Travertine

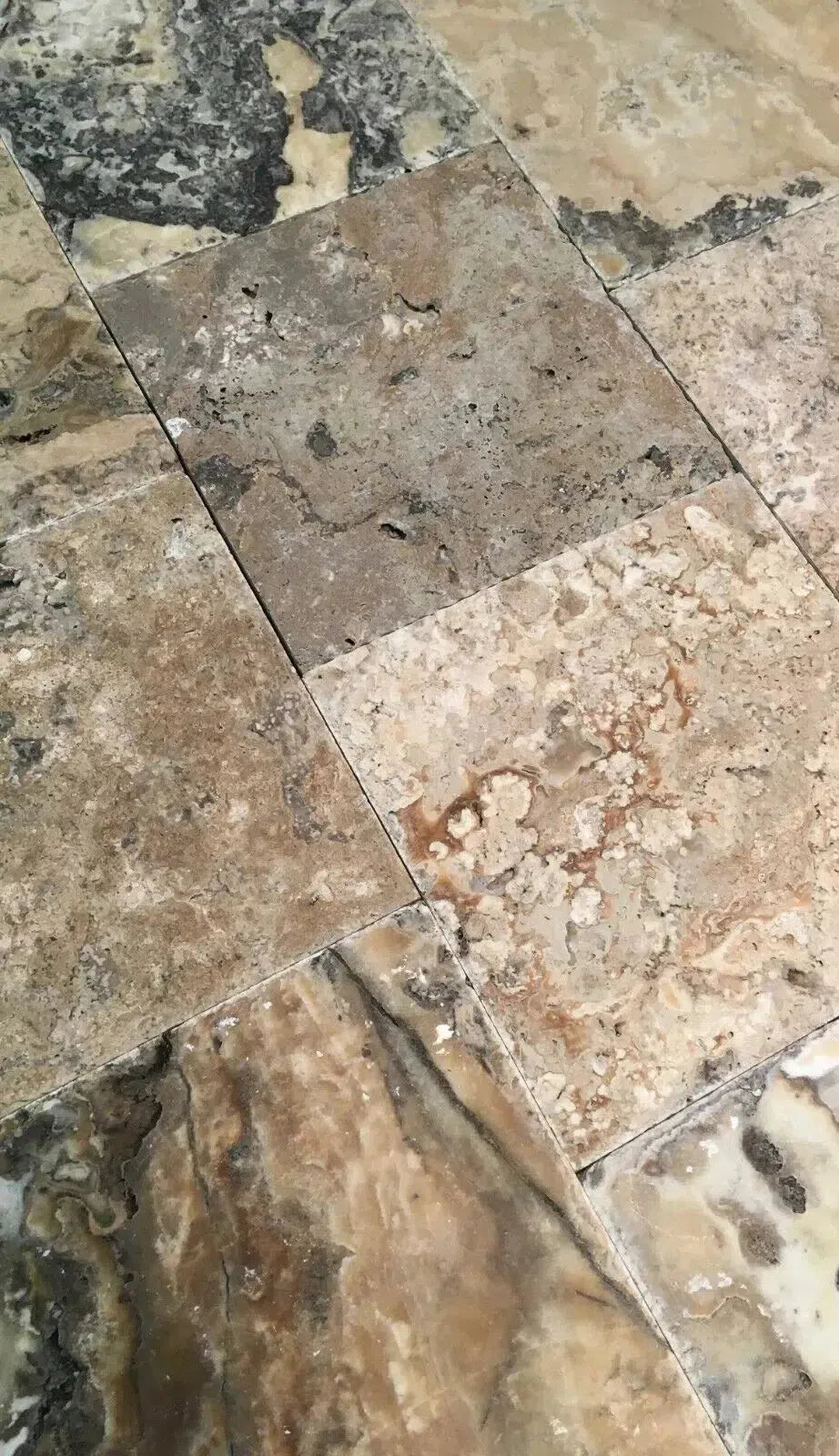

Ivory Travertine Noce Travertine

Noce Travertine Exotic Noce Travertine

Exotic Noce Travertine Scabos | Autumn Leaves Travertine

Scabos | Autumn Leaves Travertine Silver Travertine

Silver Travertine Exotic Travertine

Exotic Travertine Checkerboard

Checkerboard

Patterned Tile

Patterned Tile

Shop By Material

Shop By Material

Travertine

Travertine Marble

Marble Limestone

Limestone Soap Stone

Soap Stone Quartz

Quartz Granite

Granite Shop By Name

Shop By Name

Absolute Black Granite

Absolute Black Granite Atlantic Gray Marble

Atlantic Gray Marble Antico Onyx Travertine

Antico Onyx Travertine Bianco Congelato Dolomite

Bianco Congelato Dolomite Bianco Venatino (Bianco Mare) Marble

Bianco Venatino (Bianco Mare) Marble Calacatta Oliva Marble

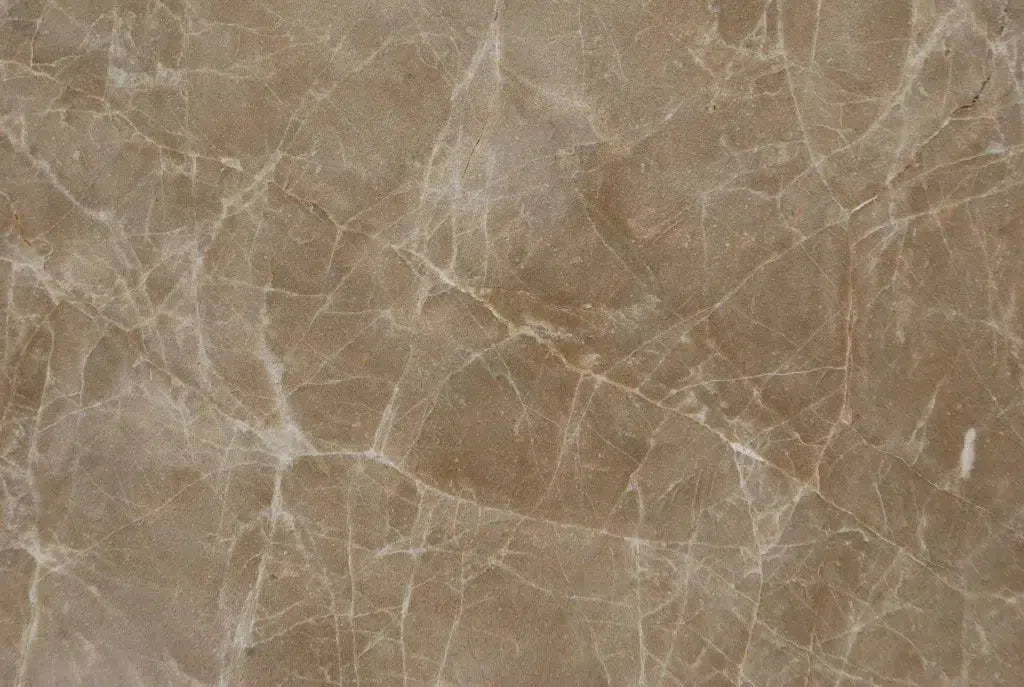

Calacatta Oliva Marble Cappuccino Marble

Cappuccino Marble Custom-Made Mosaic

Custom-Made Mosaic Diano Royal (Queen Beige) Marble

Diano Royal (Queen Beige) Marble Durango Cream Traverine

Durango Cream Traverine Emperador Light Marble

Emperador Light Marble Empress Green Marble

Empress Green Marble Gold/Yellow Travertine

Gold/Yellow Travertine Green Onyx Marble

Green Onyx Marble Haisa Light (White Wood) Limestone

Haisa Light (White Wood) Limestone Honey Onyx Marble

Honey Onyx Marble La Travonya Travertine

La Travonya Travertine Malibu Travertine

Malibu Travertine Ming Green Marble

Ming Green Marble Mink (Equator) Marble

Mink (Equator) Marble Mixed (Ivory-Noce-Gold) Travertine

Mixed (Ivory-Noce-Gold) Travertine Oriental White Marble

Oriental White Marble Pierre Bleue (Pierre Blue) Marble

Pierre Bleue (Pierre Blue) Marble Philadelphia Travertine

Philadelphia Travertine Rosso Levanto Marble

Rosso Levanto Marble Rojo Alicante Marble

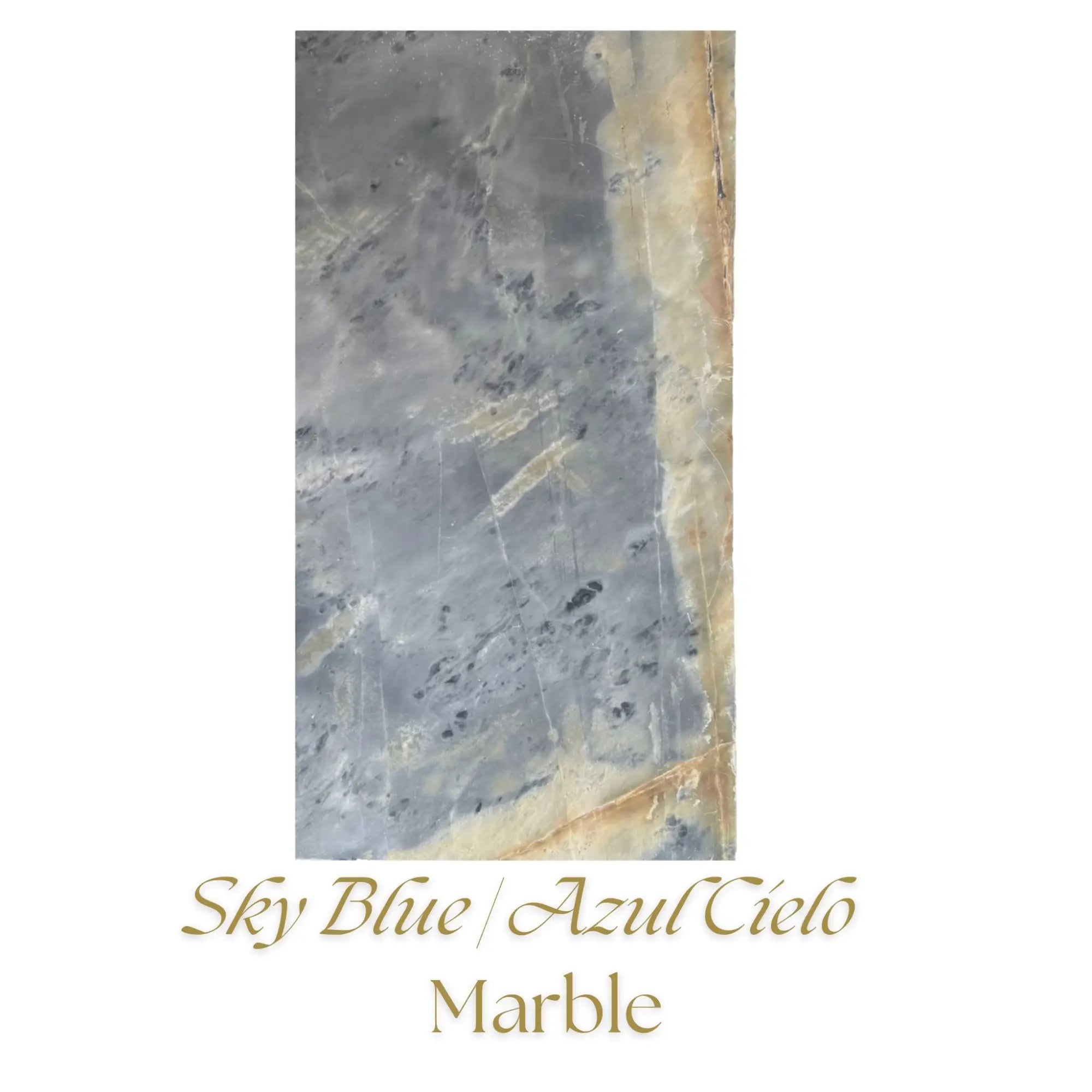

Rojo Alicante Marble Sky Blue | Azul Cielo Marble

Sky Blue | Azul Cielo Marble Snow White (Afyon White) Marble

Snow White (Afyon White) Marble Spanish Mix Marble

Spanish Mix Marble Storm Gray Marble

Storm Gray Marble Tundra Gray (Atlantic Gray) Marble

Tundra Gray (Atlantic Gray) Marble Valencia Travertine

Valencia Travertine Valerenga Travertine

Valerenga Travertine Walnut Travertine

Walnut Travertine White Onyx Marble

White Onyx Marble White Pearl/Botticino Beiege Marble

White Pearl/Botticino Beiege Marble Shop By Type

Shop By Type

Marble Tiles

Marble Tiles Marble Mosaic

Marble Mosaic Travertine Tiles

Travertine Tiles Travertine Mosaic

Travertine Mosaic 4 pcs Versailles Pattern / French Pattern Set

4 pcs Versailles Pattern / French Pattern Set Molding/Trim

Molding/Trim Border/Listello

Border/Listello Ledger-Panel

Ledger-Panel Checkerboard

Checkerboard Patterned Tile Collection

Patterned Tile Collection  Shop By Finish

Shop By Finish

Polished

Polished Honed

Honed Brushed

Brushed Split Face

Split Face Textured

Textured Tumbled

Tumbled Accessories

Accessories

Wall Plate / Switch Plate

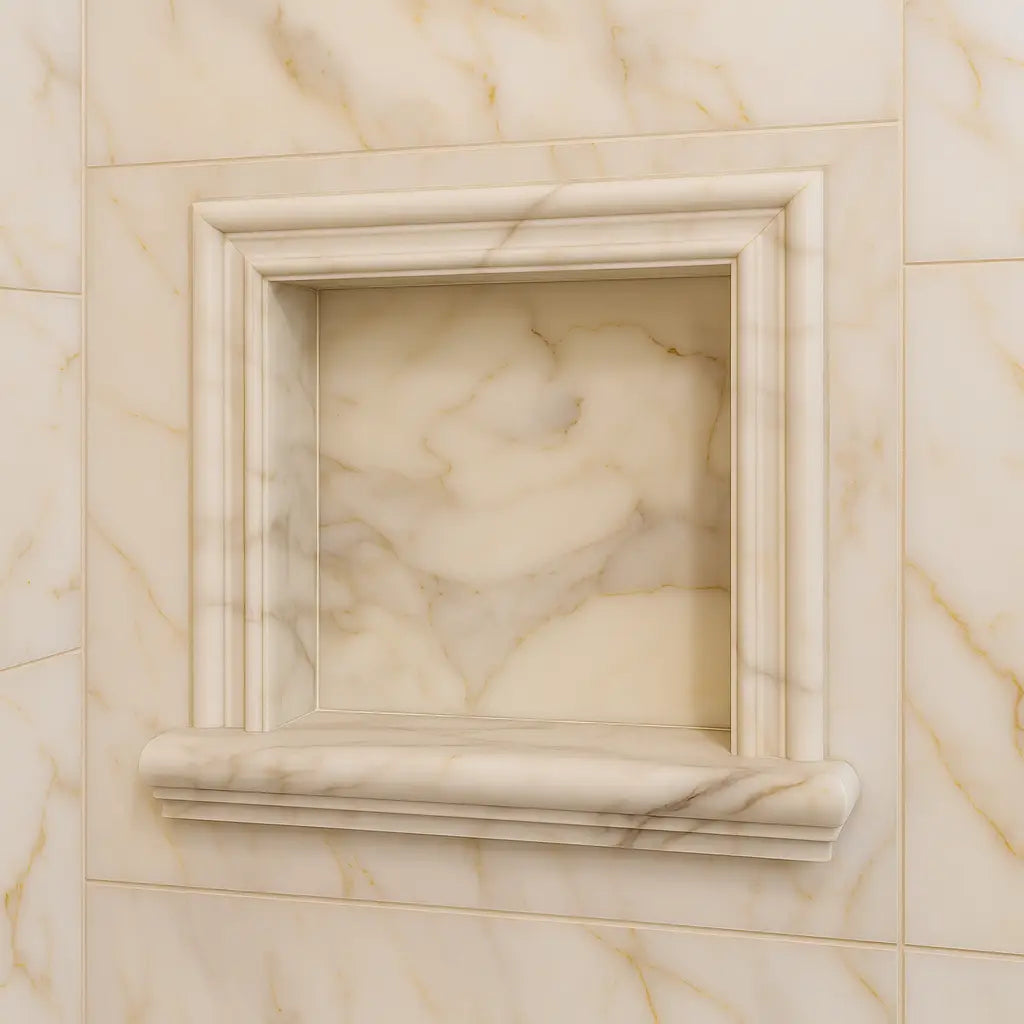

Wall Plate / Switch Plate Shampoo Niche

Shampoo Niche Corner Shelf

Corner Shelf Clearance

Clearance

Leave a comment