What Is Marble Custom Fabrication for Luxury Homes

Most American luxury homes in Southern California now feature custom marble elements, reflecting a growing demand for sophisticated, bespoke finishes. Discerning designers know that the art of marble fabrication can set a property apart both visually and in terms of investment value. In this guide, you will discover trade secrets and practical advice on achieving flawless results with American custom marble, helping you create extraordinary spaces that impress even the most discerning clients.

Table of Contents

- Defining Marble Custom Fabrication In Design

- Types Of Custom Marble Applications For Homes

- Key Steps In The Fabrication Process

- Design Flexibility And Artistic Possibilities

- Cost, Lead Times, And Common Challenges

Key Takeaways

| Point | Details |

|---|---|

| Custom Fabrication | Custom marble fabrication transforms raw stone into unique architectural elements, requiring skilled artisans to maximize aesthetic appeal and structural integrity. |

| Techniques and Applications | Various techniques such as waterjet cutting and CNC machining enable designers to create intricate features for both interior and exterior spaces. |

| Complex Processes | The fabrication process includes selecting slabs, digital templating, and specialized cutting techniques to ensure precision and artistic vision. |

| Cost and Planning | Effective cost management and timeline planning are crucial, with a contingency budget recommended to handle unexpected challenges and material variations. |

Defining Marble Custom Fabrication in Design

Marble custom fabrication represents a specialized design process that transforms raw natural stone into precisely crafted architectural elements for luxury residential spaces. This intricate technique involves transforming marble’s metamorphic crystalline structure into bespoke design solutions that elevate interior environments.

At its core, custom fabrication begins with understanding marble’s unique material properties. Unlike standard stone processing, this approach requires master craftsmen who can analyze each marble slab’s specific veining, color variations, and structural characteristics. Skilled artisans carefully select premium marble sections, mapping out precise cuts that maximize aesthetic appeal and structural integrity. The goal is creating one-of-a-kind architectural features that seamlessly integrate into high-end residential designs.

Custom marble fabrication encompasses multiple sophisticated techniques including waterjet cutting, CNC machining, hand sculpting, and specialized polishing methods. Designers work closely with stone fabricators to develop custom pieces like unique fireplace surrounds, intricately designed staircase treads, sculptural kitchen islands, and bathroom vanities that transform ordinary spaces into extraordinary environments. Each fabricated piece becomes a functional artwork that reflects the homeowner’s unique aesthetic vision.

Here’s a quick overview of major marble fabrication techniques and their unique advantages:

| Technique | Key Advantage | Typical Use Case |

|---|---|---|

| Waterjet Cutting | Ultra-precise shapes | Intricate inlays, complex forms |

| CNC Machining | Consistent repeatability | Geometric pieces, detailed cuts |

| Hand Sculpting | Artistic customization | Sculptural elements, fine accents |

| Specialized Polishing | Enhanced surface finish | Surface protection and sheen |

Pro Tip: When selecting marble for custom fabrication, always request multiple slab samples to understand the complete color and pattern range, ensuring your final design matches your exact vision.

Types of Custom Marble Applications for Homes

Luxury home design embraces custom marble applications as transformative architectural elements that elevate interior and exterior spaces. Ornamental building purposes span multiple functional and aesthetic domains, ranging from intricate decorative features to essential structural components that define a home’s character and sophistication.

Interior marble applications represent the pinnacle of custom design versatility. Homeowners and designers can create stunning custom pieces such as:- Kitchen countertops with dramatic veining and seamless edge profiles- Bathroom vanities with integrated sink basins- Fireplace surrounds featuring book-matched marble panels- Elegant staircase treads and risers- Feature wall cladding with unique pattern arrangements

Exterior marble applications extend the stone’s luxurious potential beyond interior spaces. Designers leverage custom fabrication techniques to develop impressive outdoor features like:- Poolside decking and surrounding areas- Exterior wall veneers- Landscape architectural elements- Decorative water features- Intricate garden pathways and sculpture bases

Pro Tip: When planning custom marble applications, always consider the stone’s natural color variations and select slabs that create a harmonious visual narrative throughout your design.

Key Steps in the Fabrication Process

Marble custom fabrication is an intricate process that transforms raw stone into sophisticated architectural elements. Skilled artisans navigate complex techniques to produce remarkable design solutions, blending technical precision with artistic vision.

The fabrication process typically involves several critical stages:1. Stone Selection: Carefully inspecting marble slabs for unique color patterns, veining, and structural integrity2. Digital Templating: Creating precise digital designs and measurements for exact cutting3. Cutting Techniques: Utilizing advanced methods like waterjet cutting, CNC machining, and hand sculpting4. Edge Profiling: Crafting custom edge treatments that enhance the marble’s natural beauty5. Surface Finishing: Applying specialized polishing and sealing techniques to protect and enhance the stone

Professional fabricators employ sophisticated technology and traditional craftsmanship to transform raw marble into extraordinary design elements. Advanced computer-aided design (CAD) systems allow for unprecedented precision, enabling designers to create complex geometries and intricate patterns that were previously impossible. These technologies, combined with the artisan’s expert hand, produce custom marble pieces that are both structurally sound and visually stunning.

Pro Tip: Always request detailed mock-ups and material samples before final fabrication to ensure the marble’s natural variations align perfectly with your design vision.

Design Flexibility and Artistic Possibilities

Custom marble fabrication unlocks extraordinary design potential for luxury homes, offering unparalleled creative expression through intricate artistic techniques and structural innovations. The material’s inherent versatility allows designers to transform natural stone into breathtaking architectural elements that transcend traditional design boundaries.

Marble’s design flexibility manifests through multiple creative approaches:- Geometric precision: Creating angular, contemporary forms- Organic sculpting: Developing fluid, naturalistic shapes- Layered compositions: Combining multiple marble types and colors- Textural variations: Exploring different surface treatments like honed, polished, and brushed finishes- Translucency manipulation: Leveraging marble’s unique light-filtering qualities

Designers can push artistic boundaries by integrating marble with unexpected materials and exploring innovative fabrication techniques. Advanced technologies like digital scanning, 3D modeling, and precision water jet cutting enable unprecedented design complexity. These methods allow for creating intricate patterns, ultra-thin marble panels, and custom architectural features that were previously impossible, bridging traditional craftsmanship with cutting-edge design innovation.

Pro Tip: Consider experimenting with book-matching marble slabs to create mirror-image patterns that transform surfaces into stunning visual narratives.

Cost, Lead Times, and Common Challenges

Custom marble fabrication involves complex financial and logistical considerations that require meticulous planning and expertise. Strategic cost management and timeline coordination are critical to successful project execution, with multiple factors influencing overall project investments.

Cost factors for marble fabrication include:- Marble quality and rarity- Design complexity- Size and scale of the project- Specific fabrication techniques required- Transportation and installation logistics- Skilled labor requirements- Specialized equipment and tooling

Lead times for custom marble projects typically range from 6 to 16 weeks, depending on project intricacies. Designers and homeowners must anticipate potential challenges such as material variations, potential transportation risks, and precise fabrication requirements. Unexpected complications can arise from natural stone’s inherent variability, including color inconsistencies, structural imperfections, and potential damage during handling or installation.

This table summarizes major challenges and strategies for successful marble fabrication projects:

| Challenge | Risk Area | Recommended Strategy |

|---|---|---|

| Natural Variation | Inconsistent coloring | Approve slabs before cutting |

| Complex Installation | Damage during handling | Hire experienced installers |

| Lead Time Delays | Project slowdowns | Include extra time in schedule |

| Budget Overruns | Unexpected expenses | Build in 15-20% contingency fund |

Pro Tip: Build a 15-20% contingency budget and timeline buffer into your marble fabrication project to accommodate potential unexpected challenges and material variations.

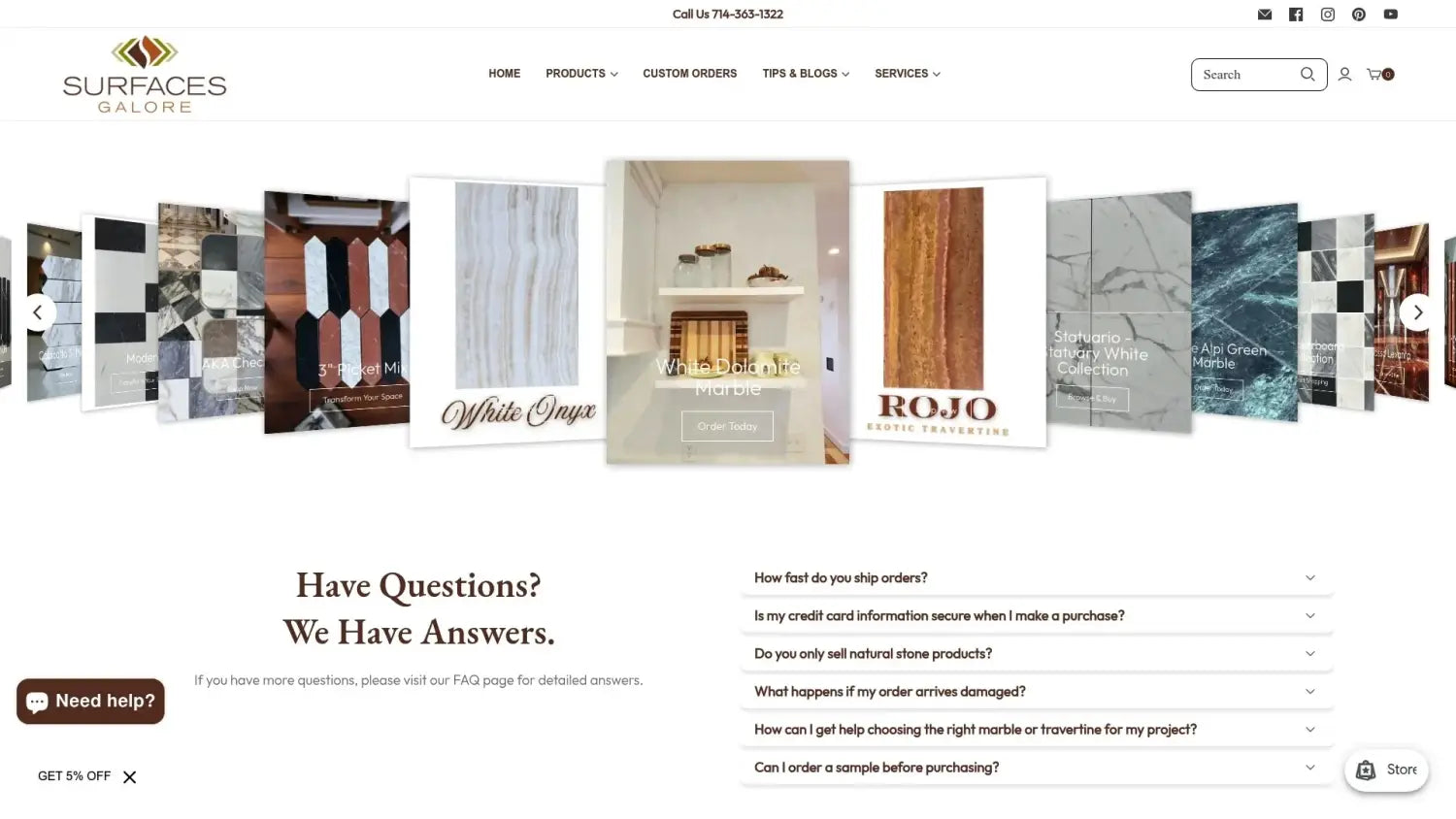

Elevate Your Luxury Home with Custom Marble from Surfaces Galore

Transforming raw marble into breathtaking architectural features requires not just skilled craftsmanship but access to the finest natural stone. The challenges of managing marble’s natural variations, ensuring precise cuts, and achieving perfect finishes can feel overwhelming. At Surfaces Galore, we understand these pain points and are dedicated to providing premium marble slabs and decorative pieces that meet your exact design vision.

Whether you are a designer, contractor, or homeowner aiming to craft unique kitchen countertops, sculptural vanities, or elegant staircase treads our extensive collection is curated to inspire and deliver. With nationwide shipping from Anaheim California, you gain direct access to authentic durable marble that supports intricate fabrication techniques and stunning artistic possibilities.

Start your luxury marble project on the right foot explore our full range of natural stone at Surfaces Galore today.

Discover how quality materials simplify custom fabrication processes and reduce costly delays. Visit Surfaces Galore now to find the perfect marble slab for your next masterpiece and bring your sophisticated design ideas to life with confidence.

Frequently Asked Questions

What is marble custom fabrication?

Marble custom fabrication is the specialized process of transforming raw marble into bespoke architectural elements for luxury homes. This involves techniques such as waterjet cutting and CNC machining to create unique design features.

What techniques are commonly used in marble custom fabrication?

Common techniques include waterjet cutting for precise shapes, CNC machining for consistent repeatability, hand sculpting for artistic customization, and specialized polishing to enhance surface finishes.

How long does the marble custom fabrication process typically take?

The lead times for custom marble projects usually range from 6 to 16 weeks, depending on the complexity of the design and specific fabrication requirements.

What factors influence the cost of marble custom fabrication?

Cost factors include the quality and rarity of the marble, design complexity, project size, specific fabrication techniques, transportation logistics, and labor requirements.

Leave a comment